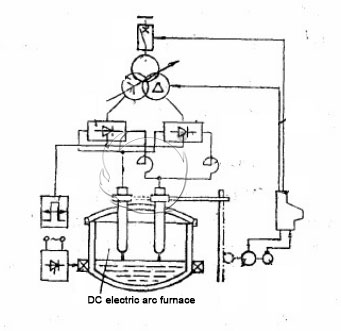

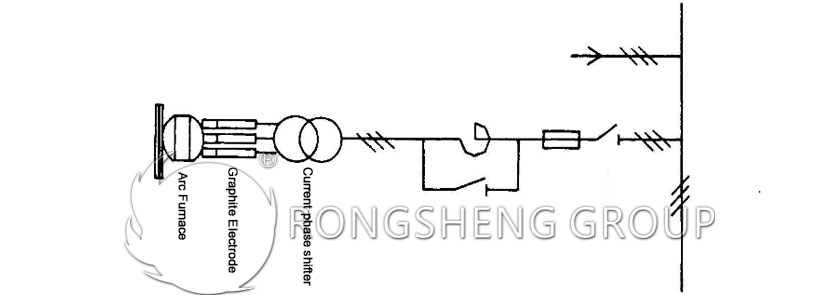

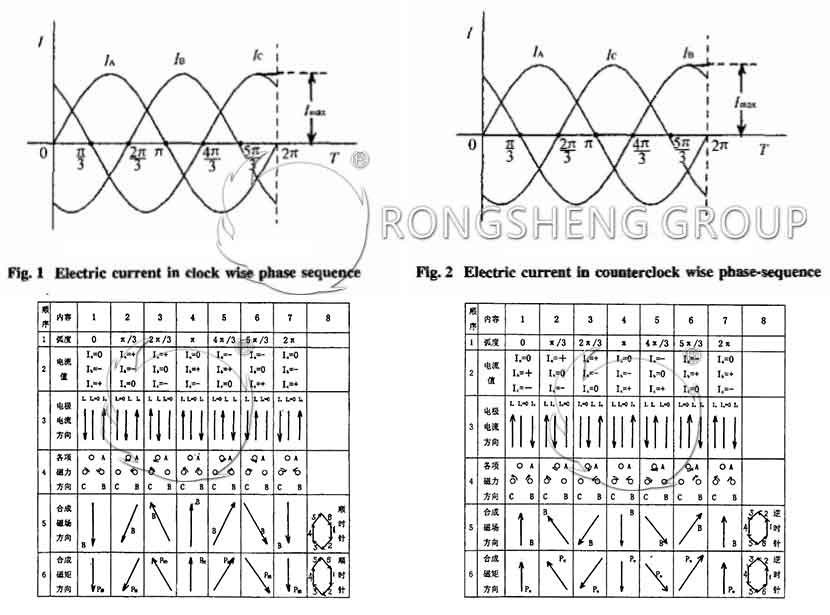

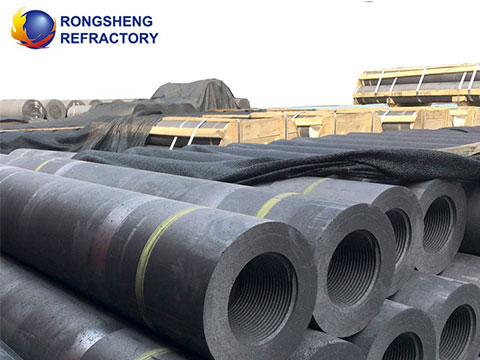

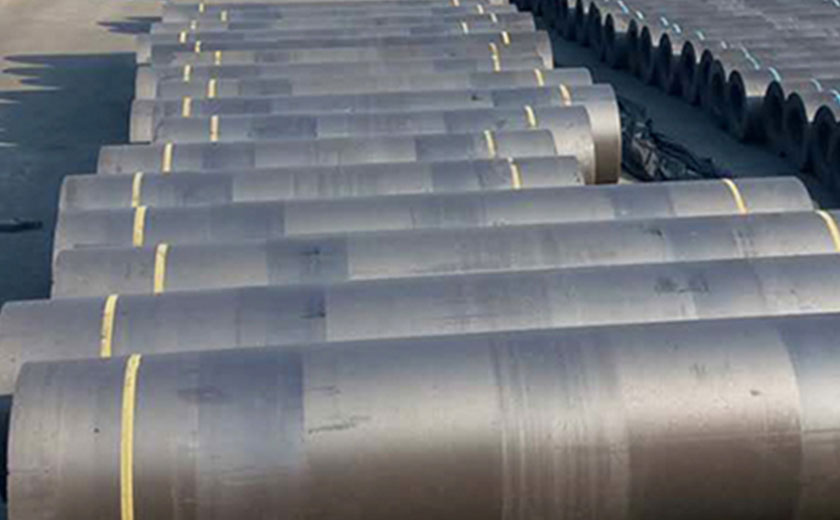

φ700mm UHP graphite electrode is used in large volume UHP DC-ARC furnace as high-temperature resistance, electrical conducting graphite materials, which is well-sold in domestic and foreign markets and has a high value because of its high-tech and complicated processing procedure. As now, with the continuous improvement of steelmaking requirements, the production and use of graphite electrodes are developing in the direction of high quality and ultra-high power. Therefore, the produce and usage of φ700mm UHP Graphite Electrodes Nipple are gradually increasing.

During producing φ700mm UHP graphite electrode, a higher requirement to prepare graphite electrodes nipple is needed because of the nipple as joint bears higher smelting requests. Therefore, the small-scale and middle-scale experiments were carried on in the lab, using high-grade petroleum needle coke X-grade SUMITOMO coke as a skeleton, Tianjin modified pitch as binder, with various process formulas and two additives to investigate the preparing process and producing techniques.

During small-scale experiments, the size distributions of formulas were selected by trying measuring vibrated bulk densities of a lot of mixtures. On the basis of them, 9 experimental formulas were designed and carried out. The suitable formulas were optimized by a polarized light microscope and measured results of samples.

A small-scale experiment shows that some formulas are gained by the method of measuring vibrated bulk density, whose characteristics are intermittent size distribution and continuous size distribution. Samples’ properties based on formulas derived from intermittent size distribution are better than the ones based on formulas derived from continuous size distribution. For example, the bulk density is improved 0.02~0.04 g/cm3, flexural strength is improved 19% ~ 41%,specific electrical resistance is lowered 8% ~ 22%. Compared with middle-temperature coal tar pitch, the modified pitch can apparently improve 0.02 g/cm3 of the bulk density and 10% of the mechanical strength of graphite electrode nipple samples because of 5% higher fixed carbon and binder strength. Stearic acid should be prudently used because it lowers more than 16% mechanical strength of graphite electrodes nipple samples although it could lower the softening point and viscosity of pitch so that it benefits for improving extrusion productivity. Adding proper additives of Fe2O3 could effectively inhabit the puffing in graphitization and improve the mechanical strength of graphite electrodes nipple samples.

On basis of small-scale experiments, selecting proper process formulas, optimizing various procedure parameters, adding procedure of impregnation and re-baking, middle-scale experiments were carried out with polarized light microscope and SEM, according to commercial production.

Results of middle-scale experiments show that increasing the content of fine particles in formulas could improve the mechanical strength of graphite electrodes nipple samples. Especially, increasing the content of ultra-fine particles in formulas could increase more than 10% of the mechanical strength of nipple samples. The procedure of impregnation and re-baking is a good method to improve the mechanical strength of graphite electrode nipple samples. But more times, improving amplitude gets less and less, and make the coefficient of thermal expansion rise.

Properties of final graphite electrodes nipple samples are as follows: bulk density 1.87 g/cm3, flexural strength 29.4MPa, Young’s modulus 17.1 GPa, coefficient of thermal expansion 1.50×10-6/℃, specific electrical resistance 4.9 μΩm, which are close to those of foreign φ 700mm UHP graphite electrodes nipple.

Cited in the paper “Development of φ700mm Ultra High Power Graphite Electrodes Nipple”.

Want more details about the graphite electrodes, Please contact RS Graphite electrode manufacturer.