Over the past decade or so, with the optimization of short processes and the development of refining processes, EAF steelmaking furnace has been greatly improved. Mainly manifested in large-scale and ultra-high power. The power supply mode is AC and DC. The difference between the two is that there are three graphite electrodes on the top of the AC arc furnace, which are connected to A, B and C three-phase alternating current. The DC arc furnace adds a set of rectifier equipment to change the input power from AC to DC. The graphite electrode on the furnace top was changed from three to one, and a bottom electrode was added on the furnace bottom. At present, about 80% of China’s steel-making enterprises still use AC arc furnaces.

AC Arc Furnace Electrodes Loosening

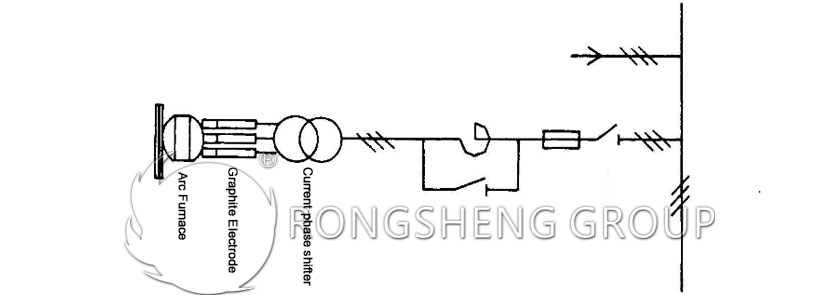

In AC arc furnace steelmaking, the current and voltage transmitted from the short wire are then transmitted to the electrode through the electrode holder. And an arc is generated between the electrode and the charge to melt the scrap. Only then can other steelmaking processes be completed. As shown below.

Over the years, the loosening of the AC arc furnace electrodes has frequently occurred. The graphite electrodes or the nipples electrodes thread is damaged and cannot be reused, and the consumption is increased, which brings direct or indirect losses to the steel mill and the graphite electrode manufacturers. It even caused the steel mill to question and claim the quality of the graphite electrode from the manufacturing plant.

Effect of Three-phase Alternating Current on Graphite Electrode

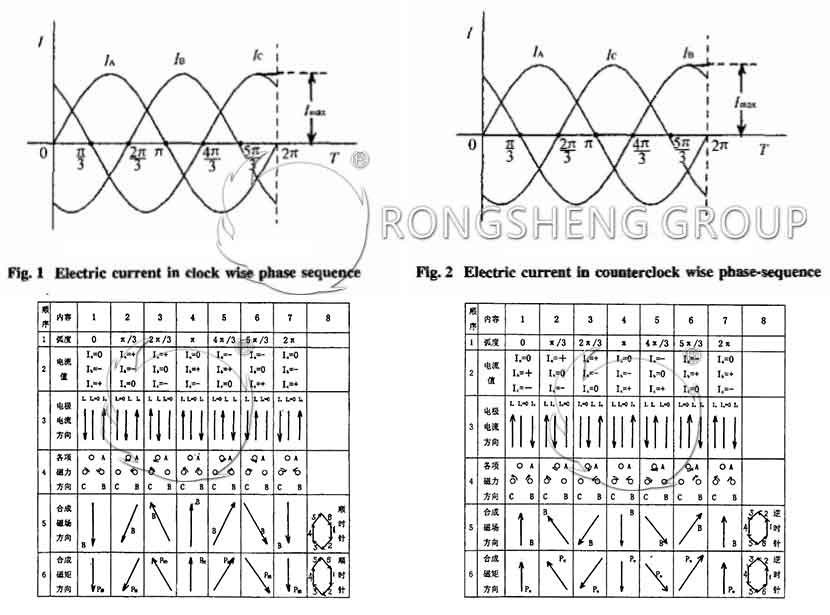

To this end, graphite electrode manufacturers start qualitative analysis from the perspective of electric and magnetic fields by consulting relevant data. It was found that the direction of the phase sequence has a great influence on the loosening of the electrode.

A, B, and C three-phase AC arc furnaces will generate a rotating magnetic field and a rotating magnetic moment to the electrodes. When A, B, and C are in the clockwise phase sequence, the direction of the rotating magnetic distance is also clockwise, which is exactly in the same direction as the electrode thread loosening, which is easy to cause the electrode joint to loosen. Conversely, when A, B, and C are in the counterclockwise phase sequence, the purpose of tightening the electrode joint can be achieved.

Conclusion

Based on the above analysis, we have taken corresponding improvement measures for the loosening of electrodes in some steel mills. Adjusting the phase sequence in time has obtained obvious results. For example, the electric arc furnaces of a company’s steelmaking plant have loosened multi-phase electrodes after they were put into production. After adjusting the phase sequence counterclockwise, the arc furnace electrodes did not come off again.

If your AC arc furnace, during the smelting process, if the electrodes frequently loose and fall off. Please check the phase sequence first to ensure that the phase sequence is adjusted to the counterclockwise direction. Then determine whether the electrode is loose due to other reasons. This can reduce the cost of consumption and improve economic efficiency.