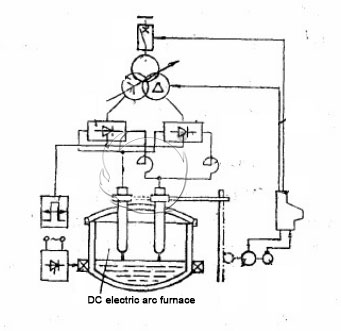

Optimizing EAF Efficiency with Rongsheng Arc Furnace Electrodes. In modern steelmaking, electric arc furnaces (EAFs) play a vital role in producing high-quality steel with energy efficiency and environmental responsibility. The success of every EAF operation depends not only on precise EAF calculation but also on the performance of its arc furnace electrodes — the key components that convert electrical energy into the intense heat required to melt scrap metal and refine molten steel.

Rongsheng, a professional graphite electrode manufacturer, provides comprehensive solutions that integrate technical understanding of furnace operation with advanced electrode production. Through decades of experience, Rongsheng helps steel plants achieve the perfect balance between power input, electrode consumption, and productivity.

Understanding EAF Calculation – The Foundation of Efficient Steelmaking

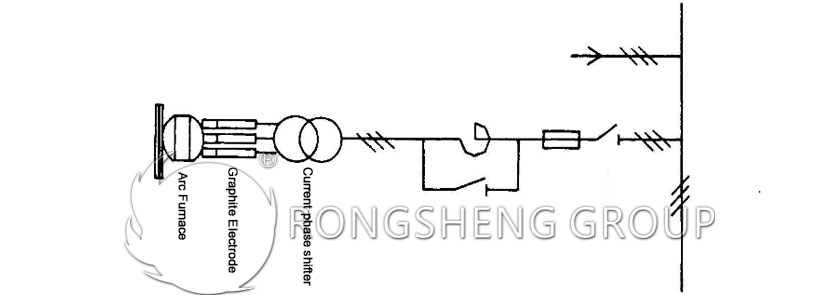

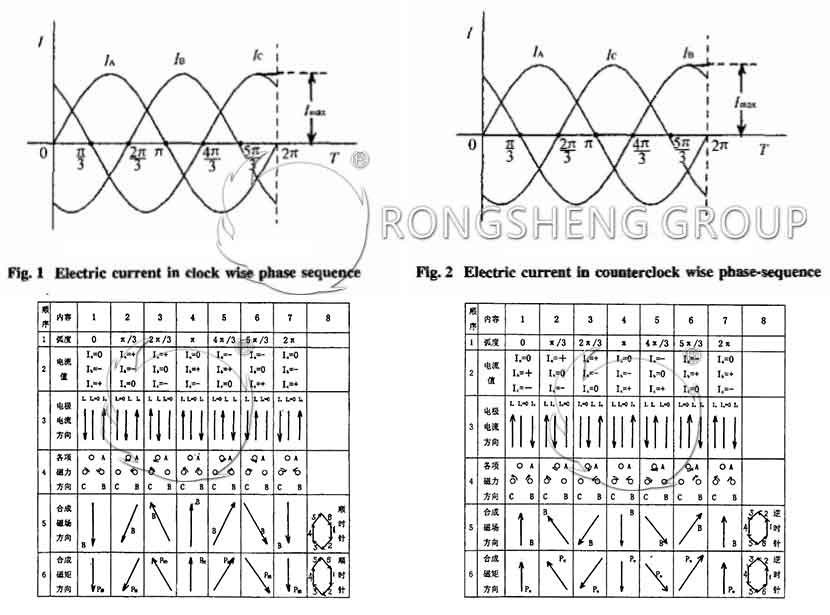

EAF calculation involves determining the optimal parameters for furnace operation — including power load, arc voltage, current density, melting time, and electrode consumption rate. These values ensure that the furnace operates safely and efficiently without unnecessary power losses or electrode wear.

Key considerations in EAF calculation include:

-

- Power Input and Arc Energy – Calculating how much power (in MW) is needed to achieve target melting rates.

- Electrode Diameter and Current Density – Ensuring electrode size matches the current load to avoid overheating or breakage.

- Furnace Geometry and Arc Length – Optimizing the space between electrodes and molten metal for maximum heat transfer.

- Consumption Rate – Estimating electrode loss per ton of steel (commonly 1.5–2.0 kg/ton for UHP operations).

Rongsheng’s engineering support helps clients analyze and adjust these parameters. The company’s data-backed approach ensures that every ton of steel melted uses the right combination of power and electrode grade — reducing waste and cost per operation.

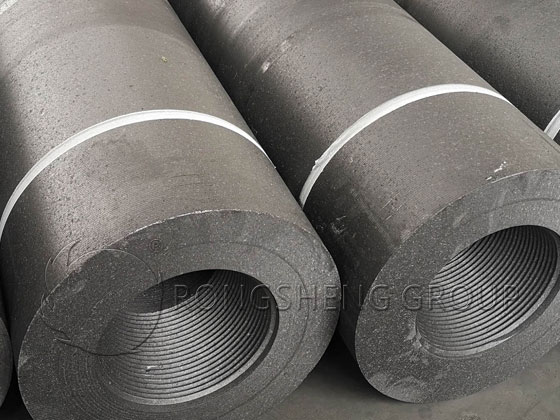

Arc Furnace Electrodes – The Power Conduit in Steelmaking

Arc furnace electrodes are the essential conductors of electrical energy in EAF operations. Their ability to withstand intense thermal, electrical, and mechanical stresses determines both furnace performance and steel quality.

Rongsheng manufactures a complete range of electrodes — from Regular Power (RP) to Ultra High Power (UHP) — each designed for specific furnace conditions.

-

- RP Graphite Electrodes – Ideal for smaller or medium-capacity furnaces operating at standard current densities.

- HP Graphite Electrodes – Suitable for furnaces requiring faster melting and moderate-to-high power input.

- UHP Graphite Electrodes – The top-grade option for high-capacity furnaces with extreme current loads and short melting cycles.

These electrodes deliver reliable conductivity, structural strength, and thermal resistance — ensuring stable arc formation during every melting stage.

Rongsheng’s Role as a Graphite Electrode Manufacturer

As a leading graphite electrode manufacturer, Rongsheng combines advanced technology with a deep understanding of EAF operational science. The company’s production process follows strict quality standards at every stage:

-

-

Material Selection – High-quality needle coke and pitch are used for consistent electrical properties.

-

Forming – The mixture is extruded into precise electrode shapes suited to the calculated furnace current.

-

Baking and Impregnation – Strength and density are increased through controlled baking and impregnation with pitch.

-

Graphitization – Conductivity is enhanced by heating up to 3000°C to transform carbon into crystalline graphite.

-

Machining – Electrodes and nipples are CNC-machined for perfect alignment and minimal energy loss during use.

-

Quality Inspection – Each batch is tested for resistivity, bulk density, and mechanical strength before shipment.

-

Rongsheng’s vertically integrated process guarantees stable quality and dimensional precision — vital for achieving accurate EAF calculations and predictable furnace behavior.

Applications of Arc Furnace Electrodes in Industry

The performance of Rongsheng’s arc furnace electrodes extends across a variety of applications. Their use is not limited to steelmaking but also extends to high-temperature material industries requiring controlled electric heating.

1. Electric Arc Furnace Steelmaking

In EAF steel production, electrodes are the heart of the process. Through their tips, high-current arcs reach temperatures above 3000°C, melting scrap and refining molten steel. Rongsheng’s UHP graphite electrodes are used here to ensure steady arcs, reduced resistivity, and long electrode lifespan — resulting in improved efficiency per melt.

2. Secondary Refining and Ladle Furnace Applications

During refining stages, electrodes maintain precise temperature control for alloy adjustment and impurity removal. HP and UHP grades are chosen to minimize consumption while maintaining consistent arc stability.

3. Submerged Arc Furnace Smelting

For the production of industrial silicon, yellow phosphorus, or ferrosilicon, Rongsheng’s RP graphite electrodes deliver reliable resistance heating, ensuring both arc and contact heat are evenly distributed in the charge.

4. Non-Ferrous Metal Processing and Specialty Materials

Electrodes are also used in copper, nickel, and high-purity material production where sustained temperature uniformity is critical for product consistency.

Each of these applications relies on accurate furnace parameter calculations to pair electrode grade and size with process requirements — an area where Rongsheng’s technical service adds clear value.

Link Between EAF Calculation and Electrode Performance

Precise EAF calculation is directly connected to the lifespan and efficiency of the arc furnace electrodes.

-

- Too High Current Density → Increases oxidation and consumption.

- Too Low Arc Voltage → Reduces melting rate and energy transfer efficiency.

- Incorrect Electrode Spacing → Causes arc instability and uneven heat distribution.

By offering both products and process guidance, Rongsheng helps furnace operators optimize these variables. The result is measurable savings in power consumption, reduced electrode wear, and improved production consistency.

Customer Case – Energy Efficiency Through Accurate EAF Calculation

A Middle Eastern steel plant partnered with Rongsheng to improve furnace efficiency. Using Rongsheng’s technical team’s EAF calculation analysis, the plant adjusted electrode diameter and current density for optimal melting balance.

After implementation:

-

- Electrode consumption reduced by 11%.

- Power consumption per ton of steel decreased by 8%.

- Production stability improved, with fewer electrode breaks and shorter melt cycles.

This case demonstrates how precise calculation combined with reliable electrodes can yield both economic and operational gains.

Why Choose Rongsheng as an Arc Furnace Electrode Partner

-

- Technical Expertise – Support for furnace optimization, electrode selection, and parameter calculation.

- Comprehensive Product Range – RP, HP, and UHP graphite electrodes for every furnace type.

- Global Experience – Trusted supplier to customers in more than 120 countries.

- Consistent Quality – ISO and CE-certified production lines ensure international compliance.

- After-Sales Support – Guidance on installation, arc adjustment, and maintenance for reduced downtime.

Conclusion

Accurate EAF calculation and high-quality arc furnace electrodes are inseparable in modern steelmaking and metallurgical operations. As a trusted graphite electrode manufacturer, Rongsheng combines technical precision with advanced production to help plants achieve efficient, reliable, and cost-effective performance.

Through careful calculation, tailored electrode supply, and global technical service, Rongsheng continues to support industries that depend on stable arc furnaces — ensuring every melt cycle delivers the best possible results.

📩 Contact Rongsheng today for technical consultation or a customized quotation.

🌐 Visit our website to learn more about our RP, HP, and UHP graphite electrodes for electric arc furnaces.