Why choose hp graphite electrode?

The high power graphite electrode is referred to as the hp graphite electrode.

Ash ≤ 0.3%, has no obvious effect on steelmaking;

Elastic Modulus can be adjusted to suit the requirements of use;

Low resistivity, good conductivity and low consumption.

Basic Characteristics & Detail Features

1. The HP graphite electrode of Rongsheng Group own the lower ash content of the petroleum coke needle coke as raw material, so the ash content of the finished product does not exceed 0.3%, and has no obvious influence on steelmaking.

2. In the production of graphite electrodes, Rongsheng Group can grasp the elastic modulus value which is more suitable for the user’s requirements by adjusting the size of the formula and the volume density of the product.

3. Selecting high-quality raw materials and improving the temperature conditions of graphitization can reduce the resistivity of graphite electrodes, which is also the advantage of Rongsheng Group.

Technical Properties of HP Graphite Electrodes

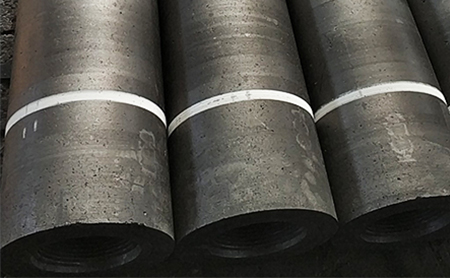

Surface Quality of HP Graphite Electrode

1. There should be less than two defects or holes on the electrode surface, the max size of which is mentioned in the below chart.

2. There should be no transverse crack on the electrode surface. For the longitudinal crack, the length should be less than 5% of the electrode circumference and the width in between 0.3-1.0mm.