The Role of the Graphite Electrode Nipples

The nipples of the graphite electrodes play a key role in the connectivity of the electrode during steelmaking. The quality of the nipple directly affects the use of graphite electrodes in electric steelmaking.

The Necessity of Graphite Electrode Nipples

No matter how the electrode quality is, if there is no good nipple with it, there will be problems in steel making.

According to relevant information, in electric steelmaking, more than 80% of electrode accidents are caused by nipple breakage and loosening tripping. Therefore, the selection of Rongsheng high-quality electrode nipple is a powerful guarantee for electric arc furnace steelmaking.

What quality indicators of graphite electrode joints have an impact on electric steelmaking?

- (1) Quality indicators such as bulk density, electrical resistivity, strength, elastic modulus, and thermal expansion coefficient of joints.

- (2) The processing accuracy of the electrode and the joint, the quality of the electrode, and the joint is good, there is no good processing precision (mainly refers to the cooperation of the electrode and the joint), and the use effect is not good.

- (3) The internal structural quality of the electrode and the joint requires that there are no cracks inside the joint that cause hidden dangers.

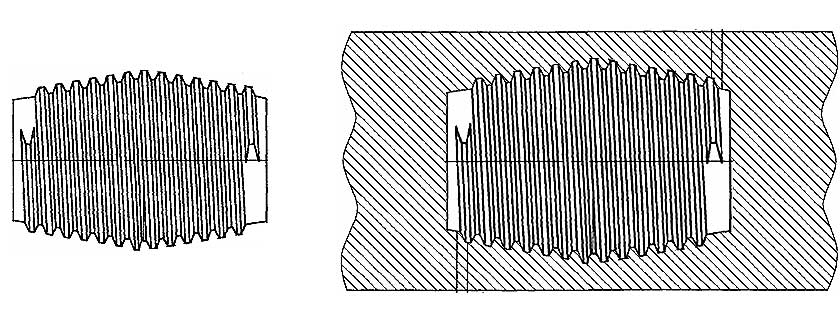

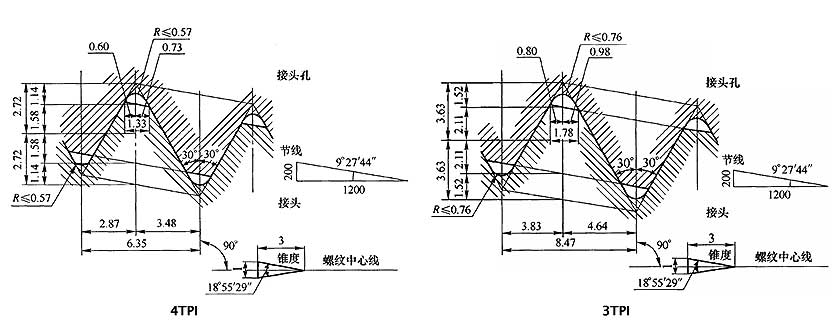

Graphite Electrode Nipples Parameters

The parameters of graphite electrode nipples (4TPI, 3TPI).

Precautions for graphite electrode nipples & bodies connection

-

(1) When the new electrode connects the nipple. It is necessary to blow out dust or dirt in the socket with compressed air.

-

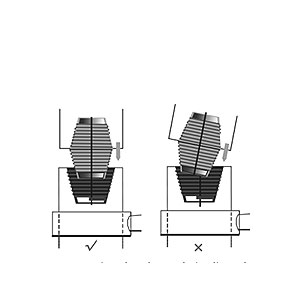

(2) When connecting, the electrode is aligned with the center axis of the nipple to which is the connection.

-

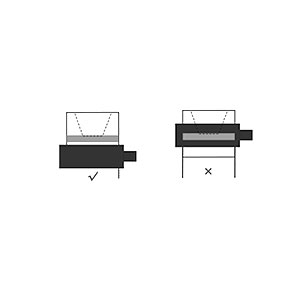

(3) The electrode clampers should be the exterior of two security lines of the nipple connection position.

-

(4) Before screwing the electrode, the dust on the surface of the electrode should be blown out of compressed air.