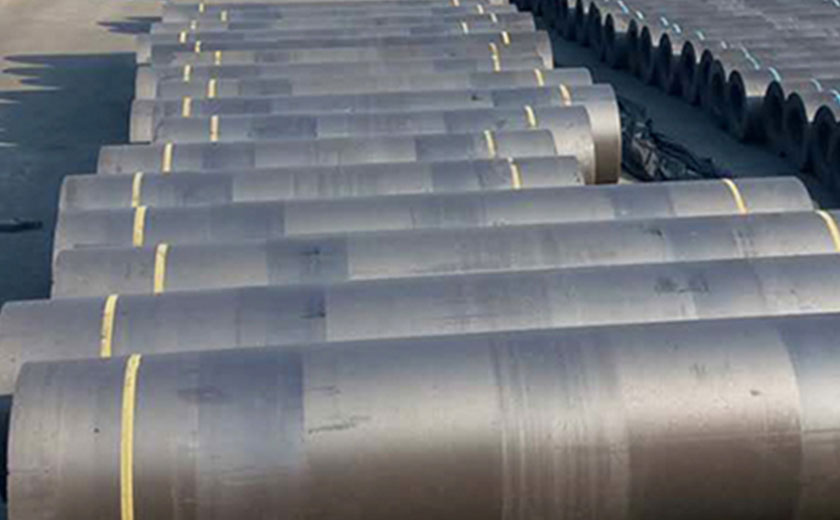

HP 450 High Purity Graphite Electrode and UHP 450 Electrode Graphite: Performance, Applications, and Manufacturing Insights. In modern electric arc furnace operations, graphite electrodes are not interchangeable consumables. Diameter, purity, current-carrying capacity, and structural stability directly influence furnace efficiency, energy consumption, and operating cost. Among the commonly used large-size electrodes, the hp 450 high-purity graphite electrode and the UHP 450 electrode graphite occupy a critical position, especially in medium-to-large electric arc furnaces that require stable arcs and high power input.

As an experienced graphite electrode manufacturer, Rongsheng focuses on producing HP and UHP 450 mm graphite electrodes that meet the demanding requirements of today’s steel, alloy, and metallurgical industries. This article introduces their technical characteristics, performance differences, and practical application value, with a clear focus on the keywords provided.

HP 450 and UHP 450 Graphite Electrodes

The number “450” refers to the electrode diameter of 450 mm, a size widely adopted in industrial furnaces that operate under high electrical loads. The difference between HP and UHP grades lies mainly in raw materials, electrical resistivity, current capacity, and thermal shock resistance.

The hp 450 high purity graphite electrode is designed for high-power operation with excellent conductivity and mechanical strength. It offers a balance between cost efficiency and performance, making it suitable for many standard electric arc furnace and ladle furnace conditions.

The uhp 450 electrode graphite, on the other hand, is engineered for ultra-high-power operation. It is capable of carrying higher current densities and enduring more severe thermal and mechanical stresses, particularly in furnaces with shorter melting cycles and higher power input.

Both types play essential roles in industrial furnace systems, but choosing the right grade directly affects productivity and electrode consumption.

Key Characteristics of HP 450 High Purity Graphite Electrode

High Purity and Low Impurities

Purity is a defining feature of HP 450 electrodes. Low ash content and minimal metallic impurities reduce the risk of contamination during melting. This is especially important for steel grades that demand strict chemical control.

Stable Electrical Performance

The hp 450 high purity graphite electrode provides reliable electrical conductivity, allowing consistent arc generation. Stable current transmission helps avoid arc fluctuation, which can otherwise cause uneven melting and increased power loss.

Good Mechanical Strength

With optimized bulk density and controlled grain structure, HP 450 electrodes demonstrate strong resistance to bending and vibration. This is essential in furnaces where electrode movement and mechanical load are frequent.

Cost-Effective for High-Power Furnaces

While not as extreme as UHP grades, HP 450 electrodes perform well under high-power conditions, offering a practical solution for producers seeking durability without excessive cost.

Performance Advantages of UHP 450 Electrode Graphite

Superior Current-Carrying Capacity

The uhp 450 electrode graphite is specifically designed to withstand very high electrical currents. Its lower electrical resistivity allows more power to pass through the electrode without excessive heat buildup.

Excellent Thermal Shock Resistance

Ultra-high-power furnaces experience rapid temperature changes. UHP 450 electrodes are manufactured to resist cracking and spalling under these harsh thermal cycles, ensuring safer and more stable furnace operation.

Longer Service Life in Intensive Operations

Thanks to premium raw materials and advanced graphitization, UHP 450 electrodes generally offer longer service life in high-intensity melting conditions. This reduces electrode consumption per ton of steel produced.

Improved Furnace Efficiency

By supporting higher power input and shorter melting times, UHP 450 electrode graphite helps improve overall furnace productivity and energy utilization.

Manufacturing Focus Behind High-Quality 450 mm Electrodes

Rongsheng’s production of HP and UHP 450 graphite electrodes follows strict quality control from raw material selection to final inspection.

Carefully Selected Raw Materials

High-quality petroleum coke and needle coke are used to ensure purity, uniform structure, and excellent electrical properties. For UHP grades, needle coke content and quality are especially critical.

Controlled Forming and Baking

Advanced forming technology ensures uniform density throughout the electrode body. Multiple baking processes strengthen the internal structure and reduce porosity, laying the foundation for stable performance.

High-Temperature Graphitization

Graphitization at extremely high temperatures transforms carbon materials into well-ordered graphite crystals. This step is essential for achieving low resistivity and high thermal stability, particularly for uhp 450 electrode graphite.

Precision Machining and Quality Inspection

Each electrode undergoes precise machining to meet dimensional tolerances, ensuring proper fit with nipples and electrode columns. Comprehensive testing is conducted to verify density, resistivity, strength, and appearance.

Application Value of HP 450 and UHP 450 Graphite Electrodes

Electric Arc Furnace Steelmaking

In electric arc furnaces, 450 mm graphite electrodes are commonly used in medium to large-capacity systems. HP 450 electrodes perform reliably in standard high-power operations, while UHP 450 electrodes are preferred for furnaces running at higher power levels with faster melting cycles.

Ladle Furnace Refining

During secondary refining, stable arcs and precise temperature control are critical. HP 450 high-purity graphite electrodes help maintain consistent heating, supporting efficient alloy adjustment and steel cleanliness.

Alloy and Special Steel Production

Producing alloy steels often involves higher temperatures and longer holding times. UHP 450 electrode graphite provides the thermal endurance and electrical stability needed for these demanding processes.

Metallurgical and Industrial Furnaces

Beyond steelmaking, HP and UHP 450 electrodes are used in industrial furnaces for silicon metal, ferroalloy production, and other high-temperature metallurgical applications where reliable power input is essential.

Economic and Operational Considerations

Selecting the correct electrode grade is not only a technical decision but also an economic one. HP 450 electrodes offer a favorable balance between performance and cost for many operations. UHP 450 electrodes, while more premium, can significantly reduce power consumption, melting time, and electrode breakage in ultra-high-power furnaces.

Over time, the improved efficiency and reduced downtime provided by UHP 450 electrode graphite can result in lower overall operating costs, especially in large-scale, continuous production environments.

Rongsheng Graphite Electrodes Manufacturer

The hp 450 high-purity graphite electrode and the UHP 450 electrode graphite are both essential solutions for modern high-temperature furnace operations. While HP 450 electrodes deliver reliable performance and cost efficiency for high-power applications, UHP 450 electrodes are designed for extreme conditions where maximum power input and durability are required.

As a professional graphite electrode manufacturer, Rongsheng continues to optimize material selection, manufacturing technology, and quality control to supply HP and UHP 450 graphite electrodes that meet the evolving demands of global industries. These products help customers achieve stable furnace operation, higher productivity, and long-term cost savings in increasingly competitive markets.

For enterprises seeking dependable 450 mm graphite electrodes, understanding the differences between HP and UHP grades is the first step toward better performance and more efficient production.