Graphite electrodes play a crucial role in modern high-temperature industries. Whether you’re melting scrap steel in an electric arc furnace or operating a refining furnace for high-grade alloys, the performance of your graphite electrode matters. At Rongsheng, we offer a full range of reliable, customizable electrodes, including RP graphite electrodes and HP graphite electrodes, designed for efficiency, durability, and consistent performance.

Let’s take a closer look at what makes Rongsheng graphite electrodes stand out — and how you can choose the right one for your plant.

What Is a Graphite Electrode and Why Does It Matter?

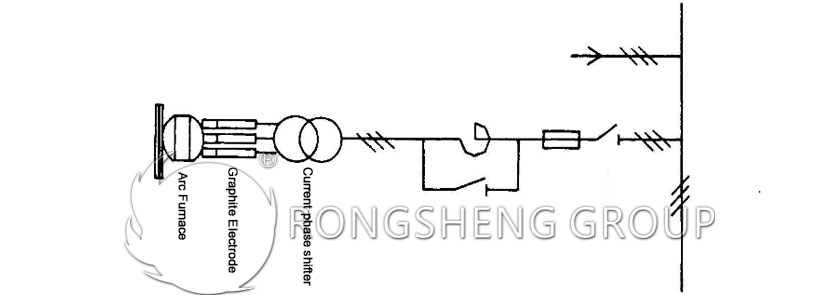

A graphite electrode is a conductor used to deliver electricity to high-temperature furnaces like electric arc furnaces (EAF) and ladle furnaces (LF). The intense heat generated at the electrode tip melts scrap metal and other raw materials, enabling the production of steel, alloys, and other industrial products.

Because the electrode works under extreme conditions, it must be made from premium carbon materials, undergo precise manufacturing, and be tested for structural strength and conductivity. Choosing the right electrode grade is critical for your process stability and cost control.

RP Graphite Electrode: A Cost-Effective Choice for Regular Loads

RP graphite electrodes, or Regular Power graphite electrodes, are suitable for EAFs operating at low current density and under standard processing conditions. They are typically used for:

-

- Small to medium-sized electric arc furnaces

- Steel plants with less aggressive power input

- Non-ferrous metal smelting

Advantages of RP Graphite Electrodes from Rongsheng:

-

- Stable Electrical Conductivity – Ensures consistent arc generation and heat transfer.

- Economical Option – Lower production and procurement costs.

- Customizable Sizes – Diameters from 100mm to 700mm, lengths up to 2700mm.

- Certified Quality – Every batch is tested to international standards.

If your plant operates under moderate conditions and seeks a balanced solution between cost and performance, RP graphite electrodes are a smart investment.

HP Graphite Electrode: High-Power Performance for Demanding Applications

For operations with higher current and larger furnace capacities, HP graphite electrodes (High Power) offer better thermal resistance and current-carrying capacity. They are ideal for:

-

- Medium to large EAFs and LF refining furnaces

- Steel production with higher energy input

- Alloy steel and stainless steel melting

Why Steel Plants Choose Rongsheng HP Graphite Electrodes:

-

- Higher Current Carrying Capacity – Suitable for tougher, high-energy production environments.

- Improved Mechanical Strength – Less breakage and longer life under stress.

- Optimized Resistivity and Density – Efficient heat management and arc stability.

- Trusted by Clients in Over 120 Countries – Proven track record in large industrial operations.

If you’re looking for performance under pressure, the HP graphite electrode is built to deliver.

Why Rongsheng? Let’s Talk About Our Advantages

When you work with Rongsheng, you don’t just get a product — you get a partner. Here’s what sets us apart:

✅ Customization

Every furnace is different. That’s why we offer custom graphite electrodes in a wide range of diameters and lengths. We also match the right nipple connection and thread to suit your plant’s setup.

✅ Longer Service Life

Our electrodes resist oxidation, cracking, and thermal shock. This means less downtime, fewer replacements, and a better return on investment.

✅ Not Easy to Break

Made from premium needle coke and processed with strict quality control, our RP and HP graphite electrodes offer strong flexural and compressive strength. You can trust them to hold up under high thermal loads.

✅ High Product Qualification Rate

Our factory adheres to ISO and CE standards, ensuring over 98% product qualification rate. Every batch is inspected for electrical resistivity, density, ash content, and mechanical performance.

✅ Competitive Pricing

Thanks to our efficient production lines and stable supply of raw materials, Rongsheng offers highly competitive prices for graphite electrodes — especially when compared with global brands of equal quality.

✅ High Repurchase Rate

Many of our clients — from steel plants to glass and rock wool producers — are long-term partners. Once they try Rongsheng, they tend to stick with us.

Applications Across Multiple Industries

While graphite electrodes are primarily used in steelmaking, they also support operations in:

-

- Glass Plants – High-temp melting processes for bottles, containers, and float glass.

- Rock Wool Plants – Electrode heating is used for mineral fiber insulation production.

- Chemical & Non-Ferrous Industries – Smelting and refining applications.

Wherever there’s heat, there’s potential for a Rongsheng electrode.

Don’t Just Take Our Word for It

A client from South Asia, operating a 20-ton electric arc furnace, recently upgraded from an older electrode supplier to Rongsheng’s HP graphite electrodes. After 3 months of continuous use, they reported:

-

- A 15% increase in electrode life

- Fewer breakages during operation

- Improved arc stability and faster melting times

That’s the kind of feedback we’re proud to earn.

Call to Action

If you’re in the steel industry or any high-temperature field, choosing the right graphite electrode is critical. Whether you’re after the economy of RP graphite electrodes or the performance of HP graphite electrodes, Rongsheng delivers reliability, customization, and excellent value.

👉 Want to learn more?

Visit Rongsheng’s website and explore our full range of graphite electrode products.

📩 Need a quote?

Send us an email today — our team will provide a free consultation and tailored quote for your next project.