In the use of arc furnace electrodes, the advantages of using DC electric arc furnace electrodes compared to AC power supply are obvious in the heat transfer of the metallurgical process.

Disadvantages of AC Power Supply for Electric Arc Furnace

When the arc furnace is powered by an AC power supply, it has four main disadvantages: unstable arc; severe voltage flicker effect; very low electrode life; furnace wall loss is particularly serious. The reason for the unstable arc is that the arc is continuously extinguished and restarted at a frequency of 50 times per second. The lag of restarting the arc depends on the position of the electrode relative to the charge, the current setting value, and the furnace atmosphere and temperature.

Advantages of DC Electric Arc Furnace Electrodes

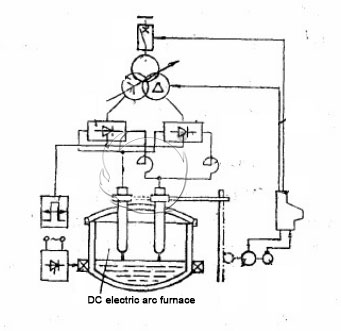

The DC arc is superior to the AC arc in terms of stability and unidirectionality, which has great benefits for heat transfer in the metallurgical process. Theoretical analysis points out that the use of direct current instead of alternating current is a major technical innovation measure. Since the DC current has no zero-crossing problem, the arc stability is improved, and the interference to the power grid is also reduced. In DC arc furnaces, the method of smelting metals using DC current is basically the same as AC arc furnaces. However, because the anode heat on the charge side is high, the “electricity-heat” conversion efficiency of the DC arc is high.

In a two-electrode DC arc furnace, the arc burns between the two electrodes and the charge. The DC arc furnace uses a thyristor converter to convert AC to DC. The electric current is transferred into the furnace by means of a large current loop and double electrodes, so there is no need to provide furnace bottom electrodes.

Graphite Electrode Manufacturers

Buy graphite electrode, graphite electrode manufacturers in india. As a manufacturer of graphite electrodes, it aims to provide high-quality graphite electrode products for electric arc furnace steelmaking. No matter where you buy the graphite electrode, please identify the graphite electrode manufacturer. If you encounter any problems in the process of using graphite electrodes, please leave a message to us, we can communicate and discuss.