Introduction to UHP Graphite Electrodes. As industries push towards higher efficiency and sustainability, ultra-high-power (UHP) graphite electrodes have emerged as essential components in the steelmaking process, particularly in electric arc furnaces (EAFs). UHP graphite electrodes are designed to handle extremely high electrical currents and temperatures, making them ideal for intensive, high-output steel production environments. Among the various sizes of UHP electrodes, the 600mm diameter variant has gained significant popularity due to its ability to strike a balance between high performance and cost efficiency.

In this blog post, we will explore the benefits, applications, and technical aspects of UHP graphite electrodes, size 600mm—a key contributor to the modern steelmaking process.

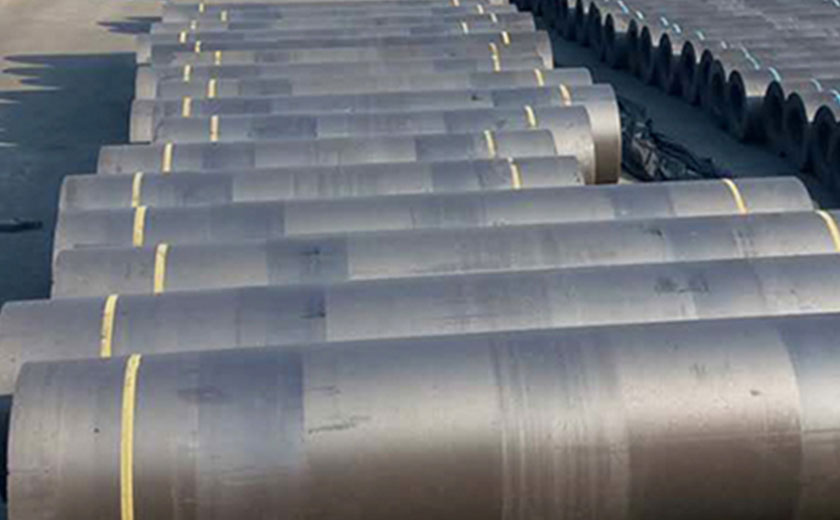

UHP Graphite Electrodes: An Overview

Graphite electrodes, especially those classified as UHP, are made from high-quality petroleum coke and needle coke. These raw materials are processed through a series of operations, including calcining, milling, molding, baking, and graphitization. The final product is a highly conductive, durable, and heat-resistant electrode that can withstand the harsh conditions of electric arc furnaces.

UHP graphite electrodes are typically used in furnaces that require extremely high temperatures and electrical energy. They offer the highest current-carrying capacity among all types of graphite electrodes, making them indispensable in large-scale steel production facilities. Their ability to operate at high power levels without significant degradation ensures that production can continue efficiently, with minimal interruptions for electrode replacement.

The Importance of Size in UHP Graphite Electrodes

The size of the graphite electrode plays a crucial role in determining its efficiency, durability, and overall performance in the furnace. UHP electrodes come in various sizes, and the 600mm diameter option is particularly valuable in large-scale industrial applications.

Why the 600mm size?

-

- Higher current-carrying capacity: The 600mm diameter allows the electrode to carry more current compared to smaller sizes, making it ideal for larger furnaces that operate at higher power levels. This size also provides greater surface area, leading to more efficient heat transfer during the steelmaking process.

- Increased durability: UHP graphite electrodes with a 600mm diameter are less prone to breakage and wear, even under intense conditions. This durability results in fewer electrode changes and reduced furnace downtime.

- Optimized performance: Larger electrodes, like the 600mm variant, contribute to improved operational stability. With a longer lifespan and higher electrical conductivity, these electrodes ensure that production can proceed smoothly and efficiently, reducing energy consumption.

Key Specifications of UHP Graphite Electrodes (600mm)

When we refer to a UHP graphite electrode, size 600mm, we are typically discussing an electrode with a diameter of 600mm and a length ranging from 2,400mm to 2,700mm. The length can vary depending on the specific furnace design and operational requirements. The key specifications of this size include:

-

- Diameter: 600mm

- Length: 2,400mm – 2,700mm

- Current-carrying capacity: Approximately 60,000 to 90,000 amperes, depending on the length and operational environment

- Apparent density: Typically around 1.70 to 1.74 g/cm³, ensuring optimal conductivity and mechanical strength

- Resistance: Low electrical resistance, which ensures efficient power transfer and heat generation during steel production

These specifications make the UHP graphite electrode (600mm) highly suitable for the rigorous demands of large electric arc furnaces.

Applications of UHP Graphite Electrodes (600mm)

The UHP graphite electrode (600mm) is primarily used in large-scale steel production, where electric arc furnaces are employed to melt scrap steel and other raw materials. Its superior electrical conductivity and heat resistance allow it to handle the extreme conditions needed for high-volume steelmaking.

Key Applications:

-

- Electric Arc Furnaces (EAFs): UHP graphite electrodes, size 600mm, are crucial in EAFs, where they help create the intense heat necessary to melt scrap steel and other raw materials. The high-power output and durability of these electrodes make them ideal for continuous operations in steel plants.

- Ladle Furnaces: After the initial melting process in EAFs, steel is often transferred to ladle furnaces for further refining. The UHP 600mm electrodes are used here to maintain the molten steel at high temperatures, ensuring the removal of impurities and improving steel quality.

- High-temperature industrial applications: Beyond steelmaking, UHP graphite electrodes are employed in other industries that require sustained high temperatures, such as silicon production and other metallurgical processes.

Advantages of UHP Graphite Electrodes (600mm)

The 600mm UHP graphite electrode offers several key advantages for industrial applications:

-

- Superior conductivity: With low electrical resistance and high current-carrying capacity, these electrodes enable efficient power transmission, reducing the energy required for steel production.

- Longer lifespan: The larger diameter and high-quality materials used in UHP electrodes ensure they can withstand the extreme conditions of steelmaking for extended periods, minimizing the need for frequent replacements.

- Reduced operational costs: The durability and efficiency of UHP graphite electrodes (600mm) help reduce both energy consumption and maintenance costs in large-scale operations.

- Environmental benefits: Electric arc furnaces using UHP graphite electrodes produce fewer emissions compared to traditional blast furnaces, contributing to more sustainable steelmaking practices.

High-Performance Steel Production – UHP Graphite Electrodes (600mm)

In the world of high-performance steel production, UHP graphite electrodes (600mm) stand out for their ability to deliver consistent, reliable, and efficient performance in demanding industrial environments. With their superior conductivity, durability, and capacity for high current, these electrodes are essential for large-scale electric arc furnaces and other high-temperature applications.

As industries continue to evolve and demand higher efficiencies, the role of precision-engineered components like UHP graphite electrodes will only grow in importance. The 600mm size offers the perfect balance between power, durability, and cost-effectiveness, making it a key asset in the quest for more efficient and sustainable steel production.