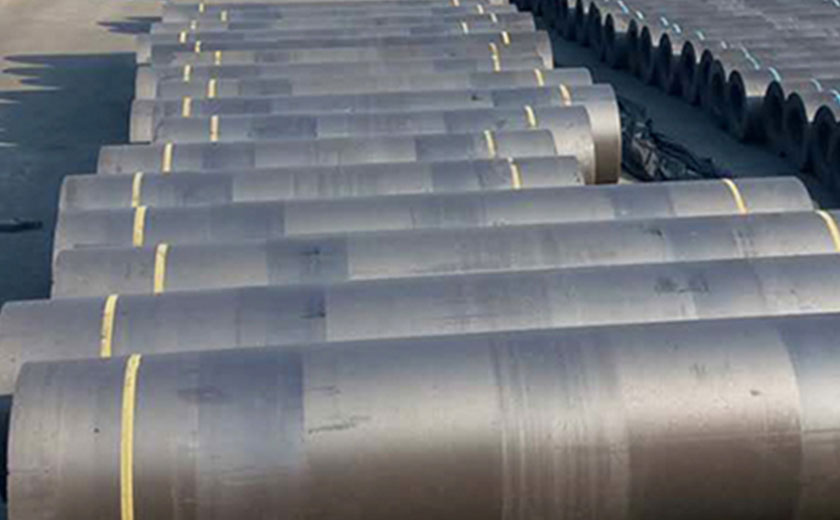

350mm UHP Graphite Electrode for Arc Furnace: Performance, Manufacturing, and Application Value. In electric arc furnace (EAF) operations, graphite electrodes are among the most influential consumables affecting productivity, energy efficiency, and operational stability. As furnace technology evolves toward higher power input and shorter melting cycles, the demand for ultra-high-power electrodes continues to grow. Among commonly used specifications, the 350mm UHP graphite electrode for arc furnace plays a key role in medium to large EAF systems that require both high current capacity and stable arc performance.

From the perspective of Rongsheng Graphite Electrode Manufacturer, this article focuses on how UHP graphite electrodes, particularly the 350mm size, support modern EAF operations, how they differ from lower grades, and why choosing the right EAF graphite electrode supplier matters for long-term furnace efficiency.

Why 350mm UHP Graphite Electrodes Matter in EAF Operations

The 350mm diameter electrode is widely applied in electric arc furnaces operating under ultra-high-power conditions. These furnaces demand electrodes capable of carrying high current densities while maintaining mechanical strength and thermal stability.

Unlike smaller electrodes used in lower-power systems, a 350mm UHP graphite electrode must handle intense electrical loads, frequent temperature fluctuations, and mechanical stresses caused by arc movement and scrap charging. For these reasons, UHP grade electrodes are often preferred over HP or RP grades in furnaces seeking higher productivity and reduced melting time.

Core Performance Advantages of 350mm UHP Graphite Electrode for Arc Furnace

High Current-Carrying Capacity

One of the defining features of a 350mm UHP graphite electrode for arc furnace use is its ability to conduct large electrical currents with minimal resistive loss. Lower electrical resistivity allows the electrode to transmit power efficiently, supporting faster scrap melting and higher furnace throughput.

Excellent Thermal Shock Resistance

Electric arc furnaces experience rapid heating and cooling cycles. UHP graphite electrodes are engineered to withstand these sudden temperature changes without cracking or spalling, reducing the risk of unexpected electrode failure.

Strong Mechanical Stability

During EAF operation, electrodes are exposed to vibration, bending stress, and impact from scrap material. The dense internal structure of UHP graphite electrodes provides superior mechanical strength, helping maintain structural integrity throughout the melting process.

Stable Arc Performance

Arc stability is essential for controlled melting and energy efficiency. A high-quality EAF graphite electrode supports consistent arc formation, reducing power fluctuation and improving heat transfer within the furnace.

Manufacturing Focus Behind Reliable UHP Graphite Electrodes

The performance of UHP graphite electrodes depends heavily on manufacturing quality. From raw materials to final inspection, each step contributes to the electrode’s reliability in arc furnace applications.

Premium Raw Material Selection

UHP graphite electrodes require carefully selected petroleum coke and needle coke with low impurity levels. Needle coke quality is especially critical, as it directly affects electrical conductivity and thermal resistance.

Precision Forming and Baking

Uniform density is essential in a 350mm electrode. Advanced forming techniques ensure even compaction, while multiple baking stages strengthen the structure and reduce internal porosity.

High-Temperature Graphitization

Graphitization at extremely high temperatures transforms carbon material into crystalline graphite. This process significantly enhances conductivity and heat resistance, defining the UHP grade’s performance characteristics.

Accurate Machining and Inspection

After graphitization, electrodes are machined to precise tolerances, particularly at the nipple connection. Strict inspection procedures verify resistivity, density, strength, and dimensional accuracy before delivery.

Application Value of 350mm UHP Graphite Electrodes in EAF Systems

Primary Steelmaking in Electric Arc Furnaces

In EAF steelmaking, 350mm UHP graphite electrodes deliver the power needed to melt scrap efficiently. Their high current capacity allows operators to increase transformer power input while maintaining arc stability, improving overall productivity.

High-Intensity Melting Operations

Steel plants aiming to shorten tap-to-tap time often operate furnaces at higher power densities. UHP graphite electrodes support this approach by tolerating greater electrical and thermal stress without compromising service life.

Ladle Furnace and Secondary Refining

Although primarily associated with EAFs, UHP graphite electrodes are also used in ladle furnaces where precise temperature control is required. Stable heating contributes to better alloy adjustment and improved steel quality.

Alloy and Special Steel Production

Special steels often require higher melting temperatures and longer refining times. UHP graphite electrodes provide the durability and electrical stability necessary for these demanding production conditions.

Economic Impact of Choosing the Right EAF Graphite Electrode

Selecting the appropriate electrode grade influences not only furnace performance but also overall operating cost. While UHP graphite electrodes typically have a higher unit price, they often reduce total electrode consumption, minimize breakage, and lower energy usage.

For furnaces operating at ultra-high power, the use of 350mm UHP graphite electrodes can result in lower cost per ton of steel produced. Reduced downtime and improved furnace stability further enhance economic benefits over the long term.

Role of Graphite Electrode Suppliers in Furnace Performance

Reliable graphite electrode suppliers contribute more than product delivery. They provide technical support, consistent quality, and supply stability, all of which are critical for continuous furnace operation.

Professional suppliers help customers match electrode specifications with furnace parameters, including transformer capacity and operating power. This ensures that the selected EAF graphite electrode performs optimally under real operating conditions.

Rongsheng’s Approach as a Graphite Electrode Manufacturer

As an experienced manufacturer of UHP graphite electrodes, Rongsheng focuses on product consistency, manufacturing reliability, and customer-oriented service. With a physical factory, advanced production equipment, and strict quality control systems, Rongsheng supplies graphite electrodes to steel and metallurgical industries worldwide.

Rongsheng’s 350mm UHP graphite electrodes are designed to support high-power EAF operations by offering stable performance, long service life, and predictable consumption rates. This helps customers optimize furnace efficiency and reduce overall operating costs.

Industry Outlook for UHP Graphite Electrodes

As electric arc furnace technology continues to expand globally, demand for high-performance UHP graphite electrodes is expected to grow. Increased emphasis on energy efficiency, recycling, and low-emission steelmaking further strengthens the role of reliable EAF graphite electrodes in modern industry.

Manufacturers capable of delivering consistent quality and technical support will play a key role in supporting this transition.

Rongsheng UHP Graphite Electrode for Arc Furnace

The 350mm UHP graphite electrode for arc furnace applications represents a critical component in modern EAF operations. With high current capacity, strong thermal shock resistance, and stable arc performance, uhp graphite electrodes enable steel producers to operate at higher efficiency and productivity.

Choosing a trusted EAF graphite electrode manufacturer and supplier is essential for achieving long-term operational stability and cost control in high-power furnace environments.

For steel plants and metallurgical enterprises seeking reliable 350mm UHP graphite electrodes for arc furnace operations, Rongsheng offers proven manufacturing capability, consistent quality, and professional technical support.

Contact Rongsheng Graphite Electrode Manufacturer today to discuss your furnace requirements and discover how high-performance UHP graphite electrodes can enhance your production efficiency and operational reliability.