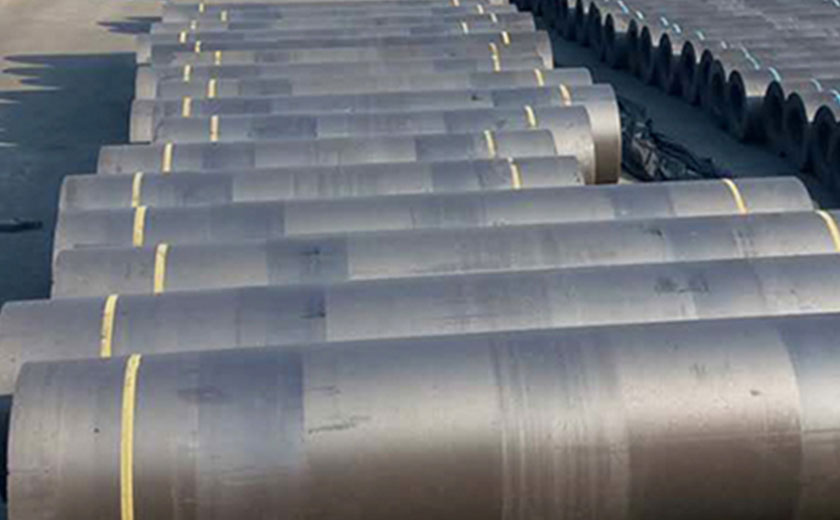

RS High Quality Graphite Electrode Manufacturer. Graphite electrodes is specifically made from petroleum coke and needle coke as raw materials, and coal tar pitch as a binder, which is prepared through calcining, compounding, kneading, pressing, calcining, graphitizing and machining and is launched in an electric arc furnace electrical energy on the charge heating and melting of the conductor.

Ultra High Power Graphite Electrode

Ultra-high-power graphite electrode can allow current densities greater than 25 A / cm2 and are mainly used in ultra-high-power steelmaking electric arc furnaces.

UHP Graphite Electrode Advantages

UHP Graphite electrode has good electrical properties and chemical stability, high mechanical strength at high temperatures, less impurities, good vibration resistance. It is a good conductor of heat and electricity.

- Processing speed is faster. Under normal circumstances, graphite machining speed can be 2 to 5 times faster than copper; and discharge processing speed is 2 to 3 times faster than copper;

- The material is more difficult to deform. Obvious advantages in the thin-walled electrode processing.

- Lighter weight. The density of graphite is only 1/5 of copper, large electrode for electrical discharge machining, can successfully lessen the gadget tool (EDM) burden; more suitable for large mould applications.

RS Graphite Electrode Manufacturer

According to the usage of distinct strength and current, the usage of exceptional refractory raw materials and manufacturing technology, may be divided into rp graphite electrodes, hp graphite electrodes, uhp graphite electrodes. Graphite electrode has proper electrical properties and chemical stability, excessive mechanical energy at excessive temperature, low impurity content, top vibration resistance, is a superb conductor of heat and electricity.