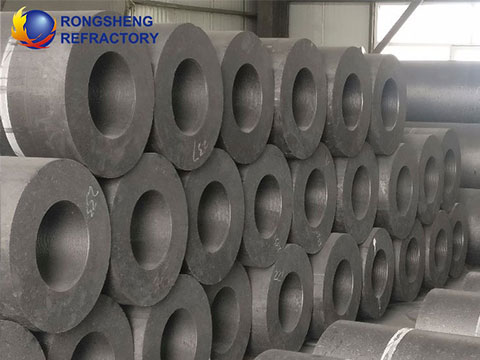

The graphite electrode body needs the graphite electrode nipple to connect them one by one in series. Therefore, they also have certain connections and differences in performance indicators.

The Performance Index Difference of Graphite Electrode Body and Nipple

(1) Resistivity. The resistivity of ordinary power graphite electrode is not more than 8.5μΩ·m, 9.0μΩ·m, 10.0μΩ·m, and 10.5μΩ·m, and the resistivity of ordinary power graphite electrode nipple is not more than 8.5μΩ·m. The resistivity of the high-power graphite electrode is not more than 6.5μΩ·m and 7.5μΩ·m, and the resistivity of the high-power graphite electrode nipple is not more than 6.5μΩ·m. The resistivity of the ultra-high power graphite electrode is not more than 6.2μΩ·m and 6.5μΩ·m, and the resistivity of the ultra-high power graphite electrode nipple is not more than 5.5μΩ·m.

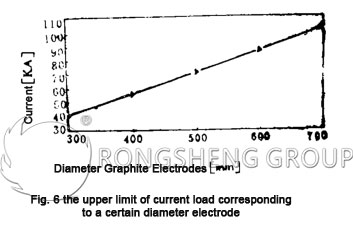

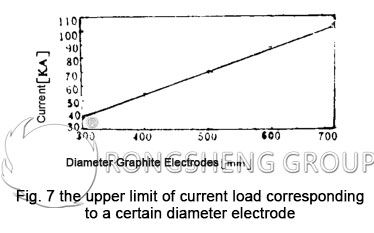

(2) Allowable current density and current load during electrode use. For graphite electrodes with a diameter of 300~500mm, the allowable current load of ordinary power graphite electrodes is 10000~20000A, and the allowable current density is 1318A/cm2. The allowable current load of the high-power graphite electrode is 13000~48000A, and the allowable current density is 1524A/cm2. The allowable current load of ultra-high power graphite electrode is 15000~55000A, and the allowable current density is 1830A/cm2.

(3) Flexural strength. The flexural strength of the ordinary power graphite electrode is not less than 6.4MPa, 7.8MPa, and 9.8MPa, and the flexural strength of the ordinary power graphite electrode nipple is not less than 13.0MPa. The flexural strength of the high-power graphite electrode is not less than 9.8MPa and 10.5MPa, and the flexural strength of the high-power graphite electrode nipple is not less than 14.0MPa. The flexural strength of the ultra-high-power graphite electrode is not less than 10.0MPa and 10.5MPa, and the flexural strength of the ultra-high-power graphite electrode nipple is not less than 16.0MPa.

(4) Bulk density. The bulk density of ordinary power graphite electrodes is not less than 1.52g/cm3 and 1.58g/cm3, and the bulk density of ordinary power graphite electrode nipples is not less than 1.68g/cm3. The bulk density of the high-power graphite electrode is not less than 1.60g/cm3, and the bulk density of the high-power graphite electrode nipple is not less than 1.70g/cm3. The bulk density of the ultra-high power graphite electrode is not less than 1.64g/cm3 and 1.65g/cm3, and the bulk density of the ultra-high power graphite electrode nipple is not less than 1.70g/cm3 and 1.72g/cm3.

(5) Linear expansion coefficient. In the temperature range of 100~600℃, the linear expansion coefficient of ordinary power graphite electrode is not more than 2.9×10-6℃-1. The coefficient of linear expansion of common power graphite electrode nipples is not more than 2.7×10-6°C-1 and 2.8×10-6°C-1, which are only used as reference indicators. For high-power and ultra-high-power graphite electrodes, the linear expansion coefficient is the main quality assessment index. The linear expansion coefficient of the high-power graphite electrode is not more than 2.4×10-6°C-1, and the linear expansion coefficient of the high-power graphite electrode nipple is not more than 2.2×10-6°C-1. The linear expansion coefficient of the ultra-high power graphite electrode is not more than 1.5×10-6℃-1, and the linear expansion coefficient of the ultra-high-power graphite electrode nipple is not more than 1.4×10-6℃-1.

(6) Consumption of steelmaking electrodes. The electrode consumption of ordinary power graphite electrodes is 46kg per ton of electric furnace steel. The electrode consumption of high-power graphite electrodes is 2.53.5kg per ton of electric furnace steel. The electrode consumption of ultra-high-power graphite electrodes is 1.12.5kg per ton of electric furnace steel.

The above is the performance index of the graphite electrode body and graphite electrode nipple. If you need to buy graphite electrodes and the matching nipple. Please contact us.