UHP Graphite Electrode 300mm Manufacturers: Manufacturing Strength, Performance, and Supplier Value. In high-temperature industrial furnaces, especially electric arc furnaces (EAFs), graphite electrodes are among the most critical consumables. Their quality directly affects melting efficiency, energy consumption, and overall production stability. Among various specifications, the UHP graphite electrode 300mm has become a widely used size in small to medium-capacity furnaces that operate under ultra-high-power conditions. As demand for stable, high-efficiency steelmaking grows, the role of professional uhp graphite electrode 300mm manufacturers and dependable graphite electrode suppliers becomes increasingly important.

Rongsheng, as an experienced graphite electrode manufacturer, focuses on delivering consistent quality and reliable supply for global furnace operators. This article discusses the technical features of UHP graphite electrode 300mm, manufacturing considerations, and how professional suppliers add value beyond the product itself.

Why UHP Graphite Electrode 300mm Matters in Modern Furnaces

The 300mm diameter electrode is commonly used in electric arc furnaces with moderate capacity but high power density. These furnaces require electrodes that can carry high current while maintaining structural stability during frequent thermal cycles.

UHP (Ultra High Power) grade electrodes are designed specifically for such conditions. Compared with HP or RP grades, UHP graphite electrodes offer lower electrical resistivity, higher bulk density, and stronger resistance to thermal shock. For furnace operators seeking faster melting, stable arcs, and reduced electrode consumption, the UHP graphite electrode 300mm provides a practical and efficient solution.

Key Performance Characteristics of UHP Graphite Electrode 300mm

High Current-Carrying Capability

One of the defining advantages of UHP graphite electrode 300mm is its ability to withstand high current loads without overheating. Low electrical resistivity allows more power to pass through the electrode efficiently, supporting shorter melting cycles and higher productivity.

Excellent Thermal Shock Resistance

In ultra-high-power operation, electrodes are exposed to rapid temperature changes. UHP 300mm electrodes are engineered to resist cracking and spalling, ensuring stable operation even during aggressive furnace start-ups and power fluctuations.

Strong Mechanical Integrity

The internal structure of UHP graphite electrode 300mm is optimized for strength and uniformity. This helps the electrode endure mechanical stress caused by electrode movement, scrap charging, and arc instability, reducing the risk of breakage.

Consistent Arc Stability

Stable arc performance is essential for controlled melting and reduced energy loss. High-quality UHP electrodes help maintain a smooth and concentrated arc, improving heat transfer efficiency inside the furnace.

Manufacturing Focus of Professional UHP Graphite Electrode 300mm Manufacturers

Not all graphite electrodes deliver the same performance, even if specifications appear similar. The difference often lies in manufacturing expertise and quality control.

Raw Material Selection

Leading uhp graphite electrode 300mm manufacturers carefully select low-sulfur petroleum coke and premium needle coke. For UHP grades, needle coke quality plays a decisive role in conductivity and thermal stability.

Precision Forming and Baking

Uniform density across the electrode body is critical. Advanced forming processes ensure consistent compaction, while controlled baking cycles strengthen the structure and reduce internal defects.

High-Temperature Graphitization

Graphitization transforms carbon into crystalline graphite at extremely high temperatures. This step significantly improves electrical conductivity and thermal resistance, defining the UHP grade performance.

Accurate Machining and Inspection

Precise machining ensures dimensional accuracy and proper nipple connection. Comprehensive inspection, including resistivity, density, and mechanical strength testing, guarantees that each UHP graphite electrode 300mm meets strict performance standards.

Application Value of UHP Graphite Electrode 300mm

Electric Arc Furnace Steelmaking

In EAF steelmaking, UHP graphite electrode 300mm supports high-power input while maintaining arc stability. This allows faster scrap melting and more predictable furnace operation, especially in facilities aiming to improve energy efficiency.

Ladle Furnace Operations

During secondary metallurgy, precise temperature control is essential. UHP 300mm electrodes help maintain consistent heating, supporting alloy adjustment and steel cleanliness without frequent electrode replacement.

Alloy and Special Steel Production

Producing alloy steels often requires higher temperatures and longer holding times. UHP graphite electrodes provide the endurance and electrical reliability needed for these demanding processes.

Industrial and Metallurgical Furnaces

Beyond steelmaking, UHP graphite electrode 300mm is used in furnaces for silicon metal, ferroalloy production, and other metallurgical applications where stable high-temperature performance is required.

The Role of Graphite Electrode Suppliers in Customer Success

Reliable graphite electrode suppliers do more than deliver products. They support customers with technical guidance, stable supply chains, and long-term cooperation.

Consistent Supply and Quality Stability

Professional suppliers maintain stable production capacity and inventory planning, helping customers avoid downtime caused by electrode shortages or inconsistent quality.

Technical Support and Application Advice

Experienced graphite electrode suppliers assist customers in selecting suitable electrode grades and sizes based on furnace conditions, power input, and production targets.

Cost Control and Long-Term Value

High-quality UHP electrodes may have a higher unit cost, but they often reduce overall operating expenses through lower consumption, reduced breakage, and improved energy efficiency.

Global Service Capability

Established suppliers with export experience can support international customers with reliable logistics, standardized packaging, and responsive communication.

Rongsheng’s Position as a Reliable Graphite Electrode Supplier

As one of the professional uhp graphite electrode 300mm manufacturers, Rongsheng integrates manufacturing strength with customer-oriented service. With a physical factory, stable production capacity, and strict quality management systems, Rongsheng supplies graphite electrodes to customers in more than 120 countries.

Rongsheng’s graphite electrodes are widely used in steel, metallurgy, and high-temperature industrial furnaces. By focusing on product consistency, performance reliability, and technical support, the company helps customers achieve longer electrode life, reduced energy consumption, and improved furnace efficiency.

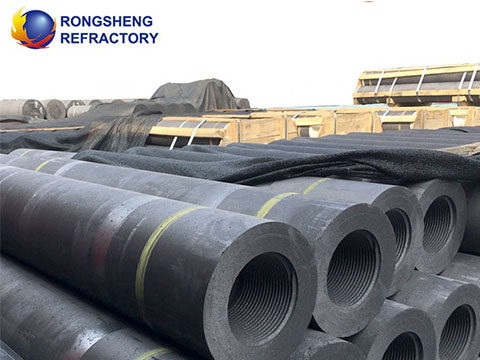

Rongsheng Graphite Electrodes

The UHP graphite electrode 300mm plays a vital role in modern ultra-high-power furnace operations. Its ability to handle high current, resist thermal shock, and maintain structural stability makes it an essential component in efficient steelmaking and metallurgical processes.

Choosing experienced uhp graphite electrode 300mm manufacturers and dependable graphite electrode suppliers is critical for long-term operational success. Manufacturing quality, raw material control, and supplier support all contribute to electrode performance and cost efficiency.

As industrial furnaces continue to pursue higher efficiency and sustainability, high-quality UHP graphite electrodes will remain a key factor in achieving these goals.

For furnace operators and procurement teams seeking a reliable UHP graphite electrode 300mm manufacturer and long-term graphite electrode supplier, Rongsheng offers proven products, stable supply, and professional technical support.

Contact Rongsheng today to discuss your furnace requirements and discover how high-quality UHP graphite electrodes can improve your production efficiency and reduce operating costs.