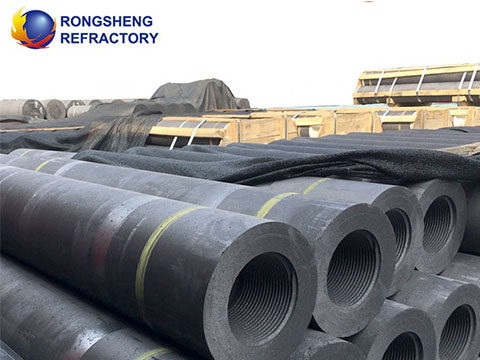

Rongsheng’s Graphite Electrode Factory – Precision Built for High-Temperature Industry. Behind every efficient electric arc furnace (EAF) stands an electrode capable of conducting immense electrical energy and withstanding extreme heat. These electrodes are the core of modern steelmaking and metallurgical processes, where performance and stability determine production success.

At the heart of this precision lies the graphite electrode factory, where raw carbon materials are transformed into durable, conductive, and high-quality electrodes. Rongsheng, a leading graphite electrode manufacturer in China, operates a fully integrated facility dedicated to producing world-class electrodes that meet the demanding standards of steel plants, foundries, and metallurgical industries worldwide.

The Foundation – Premium Graphite Raw Materials

Every high-quality electrode begins with carefully selected graphite raw materials. The purity, structure, and consistency of these materials directly influence the electrode’s electrical and mechanical performance.

Rongsheng’s production process begins with:

-

- Needle Coke: The primary ingredient, known for its low ash content and superior graphitization behavior.

- Coal Pitch Binder: Used to bond carbon particles and ensure mechanical strength after baking.

- Additives and Fillers: Adjust composition for specific conductivity and strength requirements.

These materials undergo thorough testing for chemical composition, impurity levels, and particle size before entering production. By controlling raw material quality, Rongsheng ensures that every electrode meets international performance standards.

Inside the Graphite Electrode Factory – Precision at Every Stage

Rongsheng’s graphite electrode factory integrates advanced equipment, experienced technicians, and digital process control to maintain uniform quality. The production follows several meticulous steps, each critical to the final product’s reliability.

-

-

Crushing and Screening:

The raw materials are crushed into controlled particle sizes for uniform mixing and consistent density. -

Kneading and Forming:

The crushed materials are mixed with pitch binder under heat and pressure to achieve a homogeneous mass. The mixture is then extruded into cylindrical electrode “green bodies.” -

Baking:

Electrodes are baked at approximately 1000°C to carbonize the pitch, forming a strong carbon structure. -

Impregnation (Optional for HP/UHP Grades):

Vacuum impregnation with liquid pitch fills pores, increasing density and mechanical strength. -

Graphitization:

This key stage involves heating electrodes up to 3000°C in an Acheson or LWG furnace, converting carbon into crystalline graphite. The result is excellent electrical conductivity and thermal stability. -

Machining:

CNC machines precisely shape the electrodes and cut threaded holes for nipples, ensuring accurate connection and minimal power loss during furnace operation. -

Inspection and Packaging:

Each batch is inspected for resistivity, density, bending strength, and size tolerance before shipment.

-

This manufacturing precision allows Rongsheng to supply EAF electrodes that meet both ISO and CE standards — a benchmark for global performance.

EAF Electrodes – The Power Behind Modern Steelmaking

EAF electrodes are the essential link between electrical energy and molten steel. They must endure repeated heating and cooling cycles while maintaining conductivity and structural integrity.

Rongsheng produces electrodes suitable for all EAF types and power levels:

-

- Regular Power (RP) Electrodes: Used in standard EAF operations with moderate current densities.

- High Power (HP) Electrodes: Designed for faster melting and increased productivity.

- Ultra High Power (UHP) Electrodes: Built for large furnaces with intense power input and short melting cycles.

Each grade of electrode from Rongsheng’s graphite electrode factory is engineered for specific operating conditions, ensuring stability, efficiency, and long service life.

Applications of EAF Electrodes in Industry

Rongsheng’s EAF electrodes are used across a variety of industrial sectors where high-temperature and high-energy processes are essential.

1. Steelmaking in Electric Arc Furnaces

EAFs melt scrap steel or direct-reduced iron using high-voltage arcs formed between electrodes and the furnace charge. Rongsheng’s UHP electrodes provide stable arc performance, lower consumption per ton, and reliable melting efficiency, helping steel plants achieve energy savings and improved yield.

2. Secondary Refining in Ladle Furnaces

In ladle furnaces, EAF electrodes maintain molten steel temperatures during refining and alloy adjustment. Rongsheng’s HP electrodes offer consistent conductivity, ensuring smooth heat transfer and minimal oxidation.

3. Ferroalloy and Silicon Smelting

Submerged arc furnaces used for silicon, manganese, and phosphorus production rely on robust electrodes that can handle combined arc and resistance heating. Rongsheng’s RP and HP grades offer durability under such continuous high-load conditions.

4. Non-Ferrous Metal and Chemical Production

EAF electrodes are also used to heat raw materials for copper, nickel, or titanium alloy melting and for producing silicon carbide and corundum in chemical industries.

These applications highlight the versatility and necessity of Rongsheng’s graphite electrodes in energy-intensive manufacturing.

Quality Assurance – The Core of Rongsheng’s Factory Operations

Rongsheng’s graphite electrode factory operates under strict quality management systems certified by ISO standards. Every production line incorporates automatic monitoring of temperature, pressure, and electrical parameters to ensure product consistency.

Each electrode undergoes multiple testing stages, including:

-

- Resistivity Testing: To ensure proper electrical conductivity.

- Flexural and Compressive Strength Tests: To confirm mechanical durability.

- Density Measurement: To verify impregnation efficiency and material uniformity.

- Thread Accuracy Inspection: To guarantee perfect nipple fit for minimal energy loss.

This comprehensive quality control guarantees that Rongsheng’s electrodes perform reliably in demanding furnace environments.

Sustainability and Innovation in Manufacturing

As an environmentally conscious producer, Rongsheng is committed to sustainable graphite manufacturing. The company continually upgrades furnace efficiency, reuses heat energy, and implements dust control systems to reduce emissions.

Moreover, research teams within the factory are developing next-generation graphite raw materials and impregnation technologies that further extend electrode lifespan and reduce consumption. These innovations align with global trends toward energy conservation and lower carbon steelmaking.

Why Rongsheng is a Trusted Graphite Electrode Factory

-

- Integrated Production: From raw material processing to finished electrodes under one roof.

- Large Capacity: Capable of fulfilling bulk orders for global EAF users.

- Customized Design: Electrodes tailored to specific furnace sizes, voltages, and melting conditions.

- Technical Support: Expert guidance for optimizing electrode performance and furnace operation.

- Global Network: Clients in more than 120 countries across steel, metallurgical, and chemical industries.

By combining production expertise with technical service, Rongsheng ensures that every shipment delivers both quality and operational value.

Conclusion

From carefully selected graphite raw materials to the precise engineering of EAF electrodes, Rongsheng’s graphite electrode factory exemplifies the combination of science, craftsmanship, and industry insight.

In an era where efficiency, sustainability, and reliability define industrial success, Rongsheng continues to provide graphite electrodes that power furnaces around the world — transforming energy into progress, one arc at a time.

📩 Contact Rongsheng today for a detailed quotation and consultation.

🌐 Visit the website to explore the factory’s full electrode range and manufacturing capabilities.