The relationship between graphite electrodes and steelmaking, is the graphite electrode usage. With the rapid economic development, the demand for special steels in various industries has become more and more extensive, resulting in the rapid development of electric arc furnace steelmaking technology. Large-capacity UHP eaf furnaces and large-scale external furnace refining technologies have become the symbol of modern steel . These electric furnaces use uhp graphite electrodes of different specifications. With the continuous improvement of the arc power and the continuous optimization of the smelting process technology, the physical and chemical indicators of eaf graphite electrodes are getting higher and higher, and the consumption indicators are getting lower and lower.

Judging from the average consumption level of large-scale and large-capacity ultra-high-power electric arc furnaces, the consumption of ton steel electrodes has dropped from an average of 3.5KG / T to 1.2KG / T in the past, while the average consumption of LF furnaces is less than 0.5KG / T . Because graphite electrodes occupy a certain proportion of cost in smelting and consume a large amount, all manufacturers pay great attention to the consumption and use of graphite electrodes, and they are also included in production as an important assessment index. The consumption and use of graphite electrodes in steelmaking.

Factors affecting graphite electrode consumption in smelting

In the steelmaking process, electric arc furnace smelting is divided into roughing and refining, but the graphite electrode transfers electric energy into the electric furnace and converts it into thermal energy to achieve the purpose of heating and melting solid charge. Roughing is an oxidation process with the purpose of melting scrap steel and exhausting harmful gases and impurities. Refining is a reduction process that adjusts steel grade elements and degassing to remove impurities by increasing temperature. It can be seen that electric arc furnace smelting uses graphite electrodes to adjust the furnace temperature to achieve the redox reaction and meet the steelmaking process requirements.

Development trend of smelting technology and electrode demand

The rapid development of electric arc furnaces in the steel industry has become a trend. Its characteristics are large output power, stable power coefficient, power transmission for long arc operation and development in the direction of energy saving. Therefore, the new large electric furnace has great changes compared with the traditional electric arc furnace in the past. Modern electric furnace technology pays great attention to the issue of electric furnace energy. The gas jet gun and automatic carbon oxygen gun can reduce the electrode consumption of 0.3 ~ 0.5KG per ton of steel. With the implementation of hot charging technology, the smelting time is significantly shortened, and the power consumption and electrode consumption are significantly reduced.

Large electric arc furnaces use large-capacity transformers and their overload capacity is 20%. From this point of view, the requirements for graphite electrodes in steel smelting are getting higher and higher, especially for the electrode’s quality balance, conductivity, thermal shock resistance, and oxidation resistance. Because the development of iron and steel has passed the threshold, it is developing in the direction of fine products and special varieties.

Large-scale DC and AC arcs have also been finalized; high-capacity, large-scale, large-scale blast furnaces supporting double-station LF furnaces have become a new development direction. In addition, large-scale furnaces have begun to take shape.

Now the market’s demand for graphite electrodes has developed towards multiple varieties and incremental directions. Among them: the annual demand for UHP graphite electrodes will reach 100,000 T; the annual demand for HP graphite electrodes is at least 180,000 T; the large specifications of HP graphite electrodes φ500MM and φ600MM are also moving in the direction of increase (mainly for furnaces) .

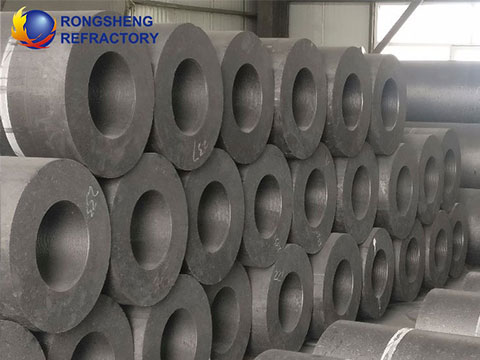

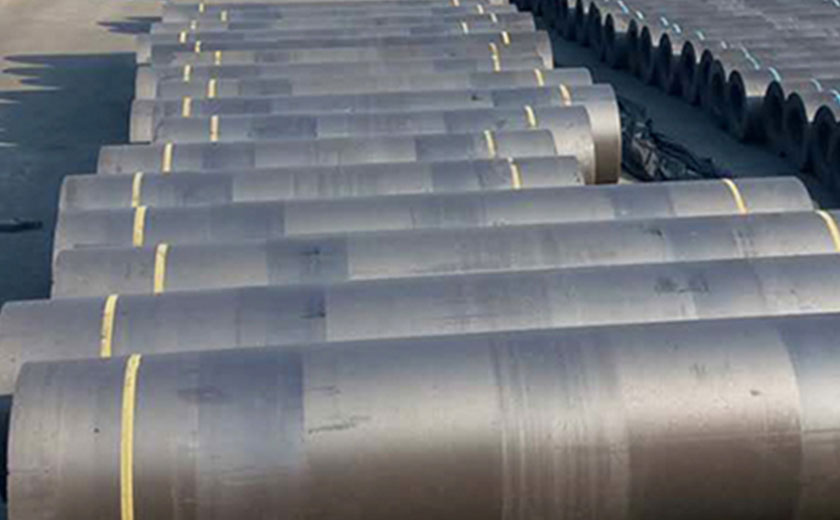

Graphite Electrode Manufacturer

RS graphite electrode manufacturer, according to the production characteristics of graphite electrodes, to provide customers with high quality graphite electrode products, rp/hp/uhp graphite electrodes. If you are in need of EAF Electrode, please contact us!