Graphite electrodes are widely used in EAF furnaces, LF ladle refining furnaces, VD/VOD vacuum furnaces, iron alloy refining furnaces, ore-fired submerged arc furnaces. The specifications of the graphite electrodes, such as the diameter of the graphite electrode, also mainly determined by the production process and technical parameters of the different furnaces.

The electric arc furnace inputs electric energy into the electric arc steelmaking furnace through the graphite electrode, and performs steelmaking by using an electric arc generated between the electrode end and the charging material as a heat source.

The electric arc furnace uses electric energy as a heat source, and can adjust the atmosphere in the furnace, which is extremely advantageous for melting steel materials containing many oxidizable elements. The high temperature flue gas of the electric furnace can be used for preheating the raw materials through technology and equipment to achieve high efficiency, energy saving, environmental protection and high yield.

With the improvement of electric arc furnace equipment and the improvement of smelting technology, the development of electric power industry, the cost of electric furnace steel is continuously reduced. Now electric furnace is not only used to produce alloy steel, but also used to produce ordinary carbon steel and iron concentrate pellets. Direct smelting, the proportion of steel produced by electric arc furnace smelting in the total domestic steel production continues to rise.

The specifications of graphite electrodes used in modern electric arc furnace steelmaking are mainly determined by the technical parameters of the steelmaking furnace production process. With the advancement of EAF steelmaking technology, steelmaking technology is developing in the direction of large-scale and ultra-high power, and the graphite electrodes matched with it are mainly large-size graphite electrodes and ultra-high-power graphite electrodes.

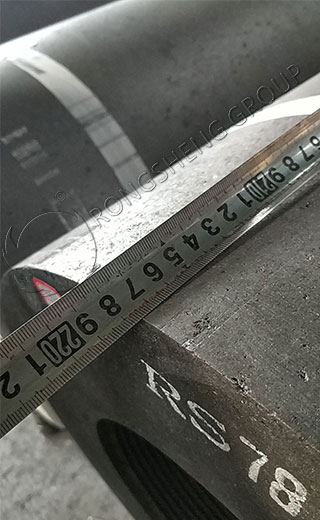

Generally, the graphite electrodes used in steelmaking furnaces are mostly ordinary power and high-power graphite electrodes. Now the use of ultra-high-power graphite electrodes is increasing year by year, accounting for almost half. The specifications of graphite electrodes are generally ∮300-∮500mm. At present, the use of large-size graphite electrodes of ∮550-∮800mm is also very large, and the length of graphite electrodes is generally between 1600-2700mm.

Since the types, specifications, and lengths of graphite electrodes used in each steel mill and each electric furnace are different, they may sometimes vary greatly. As a manufacturer and seller of graphite electrodes, Rongsheng will provide steel mills with the most needed graphite electrodes according to the information and quality requirements of the graphite electrodes used by customers’ steelmaking furnaces. In addition, we also have information on the use of graphite electrodes for some steel mills, which can provide a reference for you to purchase graphite electrodes. Contact RS for more detials.