Graphite electrodes are mainly used as conductive materials in electric smelting furnaces. Compared with other conductive materials, the biggest advantage of graphite electrode material is that it has good electrical and thermal conductivity and better toughness, can accept the impact of larger current and does not soften or melt at high temperatures. It is used as a conductive material in the steel-making electric arc furnace, and the heat energy is transferred to the charge through arc discharge to melt the steel scrap. In the submerged arc furnace for smelting yellow phosphorus and industrial silicon, the electric energy is transferred into the charge through the electrode, and the charge itself is melted by the electric resistance heating of the charge.

The Advantages of Electric Arc Furnace for Steelmaking

Compared with other steelmaking methods, electric arc furnace steelmaking has its unique advantages. Electric arc furnace steelmaking is heated by an electric arc, and its temperature can be as high as 2 000 ℃ or more. This exceeds the maximum temperature that other steelmaking furnaces can reach when burning and heating with general fuel. The thermal efficiency is higher than that of the open hearth and converter steelmaking methods. Heating with electric energy can also accurately control the temperature and can use various elements (including aluminum, iron, and other elements that are easily oxidized) to alloy steel. Various types of high-quality steel and alloy steel are smelted, such as ball-bearing steel, stainless acid-resistant steel, high-speed tool steel, electrical steel, heat-resistant steel and alloys, and magnetic materials.

At present, electric furnace smelting adopts the traditional alkaline electric arc furnace steelmaking method. The process consists of “refilling the furnace-charging-smelting (including melting period and oxidation period)-refining outside the furnace (reduction period)-tapping-continuous casting” and so on.

According to relevant data, with the continuous improvement of ultra-high power electric arc furnaces and related technologies, the electrode consumption dropped from 6.5 kg/t to 1.2 kg/t from 1965 to 2000. The power consumption is reduced from 630 kW. h/t to 290 kW. h/t and the tapping time is reduced from 180 min to 40 min.

Characteristics Requirements of Graphite Electrode Materials for Steelmaking Electric Arc Furnaces

When investigating the adaptability of graphite electrodes to steel-making electric arc furnaces, the physical and chemical properties of the materials, the matching accuracy of the electrode and the joint, the reliability of the connection, and the length of the adaptable equipment (the up and down stroke of the electrode) should be analyzed one by one. Among them, the pear blossom properties of graphite electrode materials include mechanical properties, electrothermal properties, electrical conductivity, and oxidation resistance. In addition, it is necessary to understand and master the power transmission mode, smelting method, and process of the equipment.

It is very important to correctly understand the basic characteristics of graphite electrode materials. The characteristics of different grades of graphite electrodes are basically determined by the raw materials and manufacturing methods used.

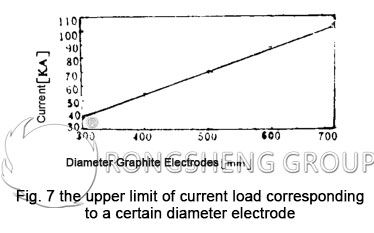

Graphite electrodes should have at least the following properties on the smelting furnace. (1) Must be able to withstand the arc current required by the steelmaking process. (2) Continuous arc generation must be maintained.

In addition, the electrode should be able to be used in a wide temperature range (that is, it can be used in a state of rapid cooling and rapid heating). In the comprehensive evaluation of the performance of the graphite electrode, the thermal shock resistance index is used as the basic standard to measure the resistance of the electrode tip.

Thermal shock resistance refers to the ability of a material to resist damage under rapid cold and rapid heat. It is a comprehensive reflection of the performance of graphite electrodes.

Compared with other conductive materials, graphite electrodes have some excellent or irreplaceable characteristics under high-temperature conditions. Graphite electrodes can be used at relatively high temperatures (sublimation temperature of 3650°C), and are the only high-temperature conductive materials that can withstand high temperatures. There is no other material that can replace them in actual use. The strength of graphite increases as the temperature rises at high temperatures. Compared with other metals, graphite has the lowest coefficient of thermal expansion. When studying the characteristics of graphite electrodes, especially the thermal stress and vibration of the connection part, the coefficient of thermal expansion and the electrical resistivity is regarded as one of the most important indicators. Therefore, it is very important to choose petroleum coke with a low CTE value to produce graphite electrodes.

The Influence of Steelmaking Technology Progress on the Consumption of Graphite Electrodes

With the large-scale and ultra-high power of steelmaking electric arc furnaces, many improvements have been made to domestic UHP electric arc furnaces. For example, molten steel is reserved at the bottom of the furnace, and long-arc bubble slag submerged arc operation is used for drainage (the power transmission system is low current and high voltage). The foaming slag operation mainly reduces the radiation of the electric arc to the furnace wall and creates conditions for the long arc operation. The long-arc operation can effectively utilize power, that is, increase power factor, increase thermal efficiency, shorten smelting time and reduce electrical energy consumption. The improvement of thermal efficiency shortens the time for melting scrap steel and smelting. The use of long arc operation increases the vibration caused by the arc but can basically avoid the collapse of the electrode during the good penetration. After the current is reduced, the tip consumption of the electrode can be reduced. In addition, shortening the smelting time in an oxidizing atmosphere means that the side consumption of the electrode is also reduced. Coupled with the auxiliary electrode spray cooling, the electrode consumption of the UHP arc furnace is greatly reduced. From the level of over 2kg/t at the end of the last century to the level of 1.5 kg/t. Sometimes, it even reaches the level of 1.2~1.3 kg/t, which is especially in line with the characteristics of high production and low consumption in China’s steel industry in recent years.

In addition, the application of technologies such as out-of-furnace refining, scrap preheating, and addition of molten iron has contributed to the reduction of electrode consumption. The automatic control of electrode lifting protection makes the phenomenon of electrode breakage caused by human operation less and less.

The advancement of steelmaking technology has brought about a substantial reduction in electrode consumption, making imported electrodes of uniform material competitive advantage. It is a top priority for domestic carbon companies to break through the quality of large-size ultra-high-power electrodes as soon as possible and strive to reduce steelmaking consumption. To learn more about graphite electrodes for steelmaking electric arc furnaces, please contact us.