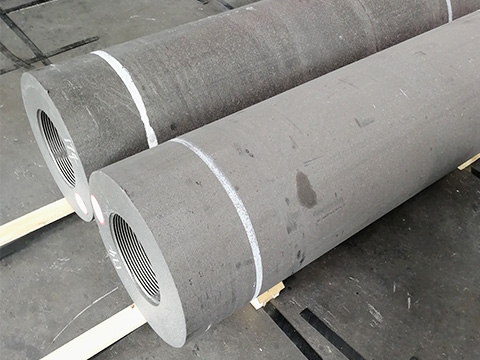

The Arc Furnace Electrodes refers to a conductor material in which an EAF furnace discharges electric energy in the form of an electric arc to heat and melt the charge. It mainly uses petroleum coke and needle coke as raw materials, coal tar pitch as binder, and is made by calcination, compounding, kneading, pressing, roasting, graphitization and machining. According to the quality index, it can be divided into rp graphite electrode, hp graphite electrode and uhp graphite electrode.

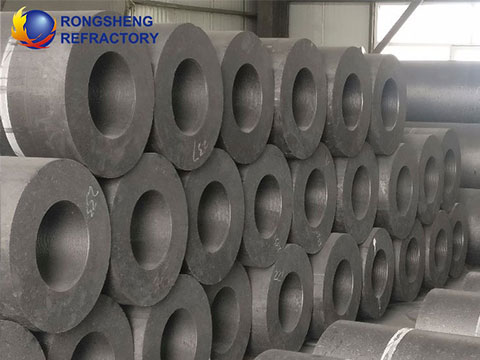

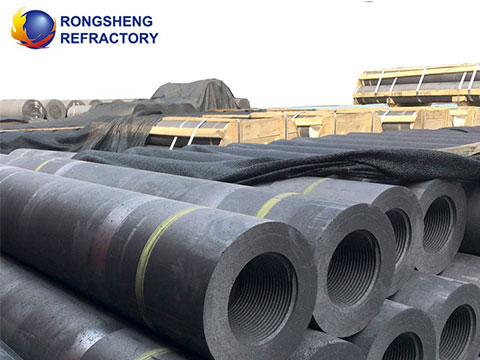

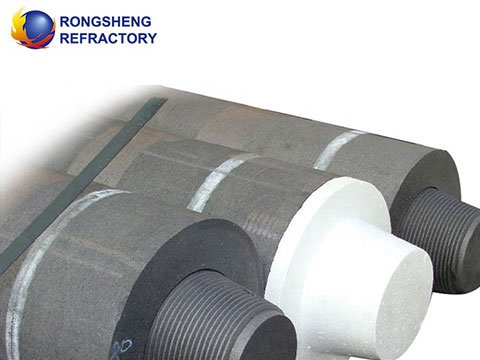

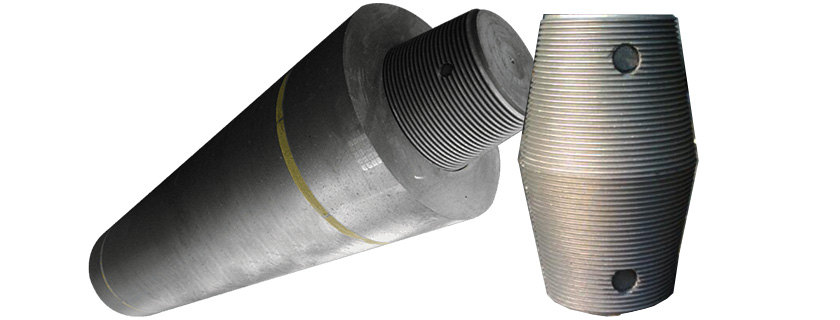

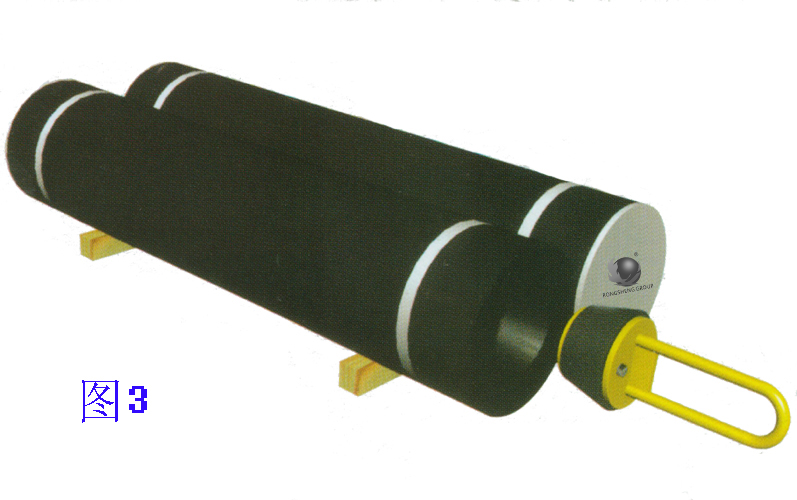

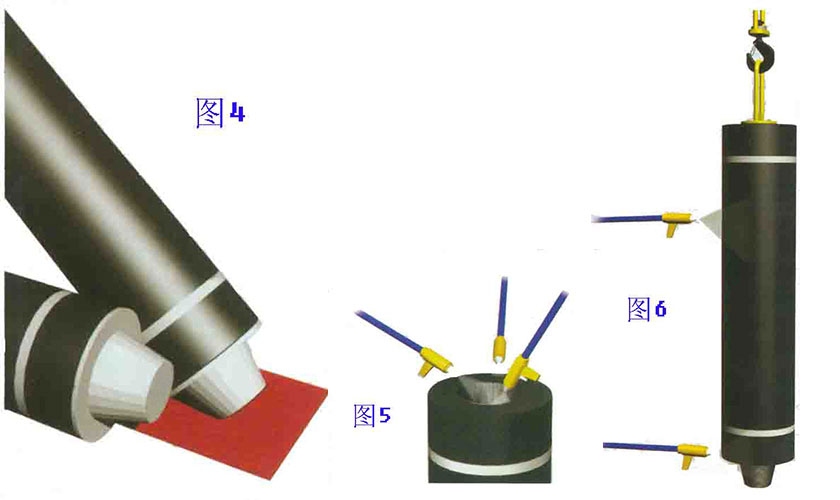

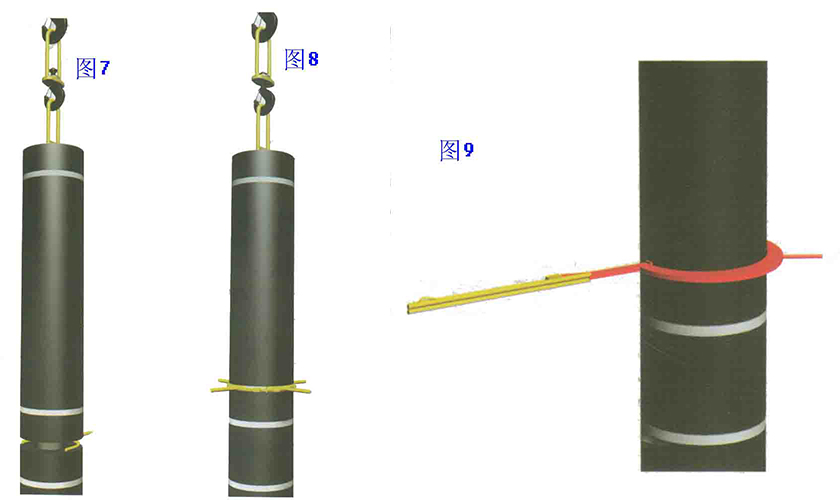

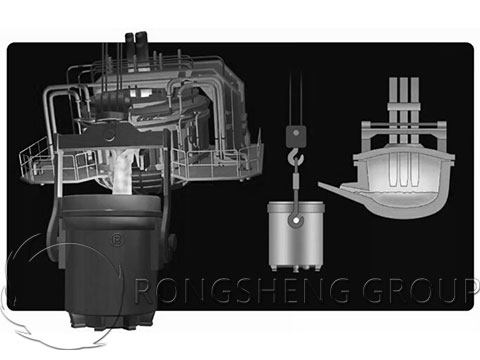

The steelmaking EAF furnace uses graphite electrode as a conductive material, and transfers the heat energy to the charge through the arc discharge to melt the charge. Commonly, an Arc Furnace Electrodes have three electrodes, each of which is composed of 3 to 4 electrodes connected by a graphite electrode nipple(tapered joint) . The electrodes are clamped by a gripper at the end of the cantilever. The cantilever is lifted together with the soft busbar that connects to the power supply.

The heat during smelting is caused by the arc discharge between the electrode and the metal charge. The arc formed by its tip converts electrical energy into heat for smelting. Because the Arc Furnace Electrodes are mostly in the furnace, they are subjected to the radiant heat of the high temperature furnace gas, the surface of the molten pool, the furnace wall and the arc tip of the electrode tip; the furnace gas washes the surface of the graphite electrode and heats the electrode by convection heating. This heat transfer is enhanced with the increase of furnace gas and material temperature and the increase of furnace gas volume.

It is because of such a harsh working environment that graphite electrode materials have some excellent or irreplaceable properties under high temperature conditions compared to other conductive materials. The Arc Furnace Electrodes can be used at a relatively high temperature, and the sublimation temperature is 3650 ° C. It is a high-temperature conductive material capable of withstanding high temperature. In actual use, no other material can be substituted; the strength of graphite increases with temperature at high temperature; graphite Compared with other metals, the coefficient of thermal expansion is the lowest.

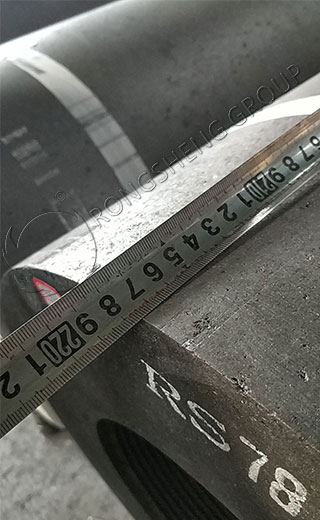

The electric furnace is equipped with a large-capacity transformer, and the electric furnace steelmaking is moving toward a large scale. The refinement of the electric arc furnace function (melting furnace and refining furnace) has increased the demand for high quality Arc Furnace Electrodes. The diameter of the DC arc furnace with graphite electrode is calculated based on the capacity of the furnace and the allowable current density of the electrode. For an ultra-high-power electric furnace of the same input power, a DC furnace using one graphite electrode has a larger electrode diameter. For example, an AC arc furnace with a capacity of 150 t uses an electrode with a diameter of 600 mm, and a DC arc furnace of the same capacity is used. For electrodes with a diameter of 700 to 750 mm, the quality requirements of the DC arc furnace for graphite electrodes are higher than those for AC arc furnaces.

If you want to know more about the Arc Furnace Electrodes, please contact us, RS Graphite Electrode Manufacturer, we will reply you in the shortest time. Providing you with higher quality arc furnace electrodes uhp graphite electrodes is our goal!