What Is a Graphite Electrode – The Core of Electric Arc Furnace Steelmaking. In the world of modern metallurgy, few materials are as critical as the graphite electrode. These cylindrical carbon products serve as the vital conductors in electric arc furnaces (EAFs), where scrap metal and other raw materials are melted to produce high-quality steel and alloys.

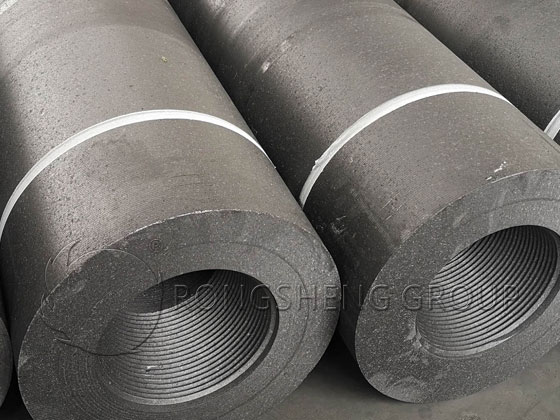

So, what is a graphite electrode? In simple terms, it’s a precision-engineered carbon rod made from high-purity materials, capable of carrying large electrical currents and sustaining temperatures that can exceed 3000°C. Its exceptional conductivity, strength, and thermal stability make it indispensable to EAF steelmaking, refining, and high-temperature material production.

Rongsheng, one of the leading graphite electrode manufacturers in China, specializes in producing durable, high-performance electric arc furnace electrodes that deliver efficiency, consistency, and long service life in demanding industrial conditions.

What Are Electric Arc Furnace Electrodes Used For?

Electric arc furnace electrodes, often referred to as EAF electrodes, are used to conduct electricity from the power source into the furnace chamber. The electric arc generated between the electrode tip and the furnace charge produces the heat required to melt steel scrap or other materials.

During furnace operation, electrodes are gradually consumed by oxidation, sublimation, and mechanical wear, which is why consistent quality and structural integrity are essential. Rongsheng’s electrodes are designed to handle these harsh conditions, ensuring minimal consumption and maximum productivity for steelmakers worldwide.

Primary uses of EAF electrodes include:

-

- Steelmaking: Melting recycled steel scrap or direct reduced iron in electric arc furnaces.

- Refining: Controlling temperature and chemistry during ladle furnace operations.

- Alloy Production: Providing heat and current in ferroalloy and silicon smelting.

- Material Manufacturing: Supplying high-temperature energy for producing corundum, silicon carbide, and other advanced materials.

Each of these applications relies on electrodes that can maintain stability under fluctuating electrical loads and extreme thermal shock — qualities that Rongsheng ensures through careful manufacturing control.

Raw Material for Electrodes – The Beginning of Quality

The performance of every electrode begins with its ingredients. The raw material for electrodes determines how well they conduct electricity, resist breakage, and handle heat cycles.

Rongsheng uses only high-quality carbon and coke-based materials sourced from trusted suppliers. These materials are carefully selected and processed before electrode forming begins.

Main raw materials for graphite electrodes include:

-

-

Needle Coke: A high-quality, petroleum-derived carbon material with low impurity content and excellent graphitization potential. It ensures high conductivity and structural strength.

-

Coal Pitch Binder: Used to bond carbon particles and give the electrode its mechanical cohesion.

-

Additives: Specialized compounds that enhance oxidation resistance, density, and surface integrity.

-

The purity and structure of these raw materials define the electrode’s lifespan and efficiency. Rongsheng continuously monitors material quality to ensure consistent performance in all production batches.

Manufacturing Process – Turning Raw Materials into EAF Electrodes

Rongsheng’s advanced manufacturing process transforms carbon-based raw materials into robust EAF electrodes suitable for industrial use. Each stage is precisely managed to guarantee consistent quality and dimensional accuracy.

-

-

Crushing and Screening

Raw materials are crushed and separated into uniform particle sizes for consistent blending. -

Kneading and Mixing

Materials are heated, mixed with pitch binder, and kneaded into a homogeneous carbon paste. -

Forming

The paste is extruded or molded into cylindrical “green” electrode blanks. -

Baking

Electrodes are baked at around 1000°C, carbonizing the pitch and giving strength to the structure. -

Impregnation

Electrodes are impregnated under vacuum with liquid pitch to increase density and reduce porosity. -

Graphitization

The most critical step: electrodes are heated to nearly 3000°C in a graphitization furnace, converting carbon to crystalline graphite for superior electrical conductivity. -

Machining

CNC precision machining ensures exact dimensions and flawless nipple threading for seamless connection between electrode sections. -

Inspection and Packaging

Each electrode undergoes mechanical, electrical, and dimensional testing before being carefully packed for shipment.

-

By controlling every step within its graphite electrode factory, Rongsheng ensures stability, uniformity, and dependability across all EAF electrode grades.

EAF Electrodes in Action – Powering the Furnace

In the electric arc furnace, three graphite electrodes are suspended vertically above the furnace charge. When current passes through them, arcs form at their tips, generating immense heat to melt scrap steel and alloy materials.

Rongsheng’s EAF electrodes are available in multiple grades:

-

- RP (Regular Power): For standard furnace operations with moderate current density.

- HP (High Power): For faster melting cycles and intermediate furnace sizes.

- UHP (Ultra High Power): For large EAFs with high current loads and shorter melting times.

Each electrode type is designed with specific mechanical and electrical characteristics suited to the user’s furnace parameters. The correct grade selection ensures reduced power loss, lower electrode consumption, and smoother furnace performance.

Why Choose Rongsheng as an Electric Arc Furnace Electrode Supplier

-

-

High-Quality Raw Materials – Every electrode begins with premium-grade needle coke and refined pitch for optimal conductivity and durability.

-

Complete Production Control – From material preparation to machining, every process occurs in-house for consistent quality.

-

Custom Solutions – Electrodes available in diameters from 100 mm to 700 mm and lengths up to 2700 mm.

-

Global Reach – Products exported to more than 120 countries, serving steel, metallurgy, and non-ferrous industries.

-

Competitive Pricing – Factory-direct pricing ensures excellent value without compromising performance.

-

Technical Support – Expert consultation for electrode selection, installation, and EAF operation optimization.

-

This combination of product quality and professional service positions Rongsheng as a trusted partner among global electrode manufacturers.

Customer Example – Efficiency Through Material Excellence

A European steel manufacturer sought to reduce electrode consumption in its 100-ton EAF. By switching to Rongsheng’s UHP graphite electrodes, engineered from premium raw materials for electrodes, the company achieved:

-

- 12% reduction in electrode wear rate.

- 8% shorter melting cycle times.

- Improved arc stability and fewer electrode break incidents.

These results highlight how high-quality materials and precise manufacturing directly enhance furnace efficiency.

Conclusion

Understanding what a graphite electrode is goes beyond its appearance — it’s about the science behind conductivity, structure, and endurance. From carefully selected raw material for electrodes to advanced manufacturing processes, Rongsheng delivers reliable electric arc furnace electrodes that form the backbone of modern steelmaking.

As industries strive for energy efficiency and sustainability, Rongsheng’s commitment to innovation ensures that every EAF electrode supports not just furnace performance, but the future of green metallurgy.

📩 Contact Rongsheng today for expert consultation or quotations on graphite electrode solutions.

🌐 Visit the website to explore electrode grades, specifications, and manufacturing insights.