Steel is a vital component in many industries, from construction to manufacturing. The demand for steel continues to increase as the world population grows, and industrialization expands. The steelmaking process is energy-intensive and requires a lot of resources. Therefore, improving steelmaking processes is essential for sustainability and profitability. One way to improve the steelmaking process is by using advanced electric arc furnace electrodes. These electrodes are an important component of electric arc furnaces, which are commonly used in steelmaking. They provide the electrical energy needed to melt scrap metal and other materials to produce new steel.

Improving Steelmaking Processes with Advanced Electric Arc Furnace Electrodes

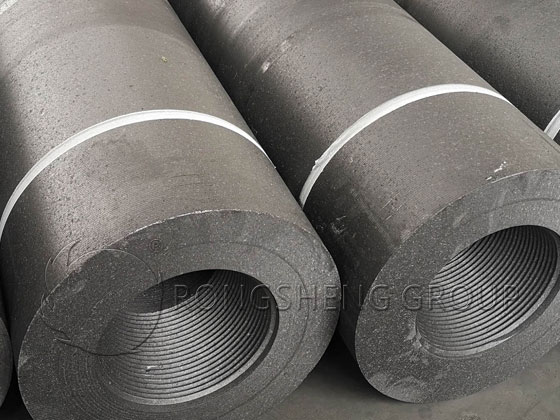

Traditionally, electric arc furnace electrodes have been made of graphite or carbon. However, these materials have limitations in terms of performance and durability. They tend to erode quickly, requiring frequent replacement, which adds to the overall cost of steel production.

Advanced electric arc furnace electrodes are made of high-quality materials that are designed to withstand the harsh conditions of steelmaking. They are typically made of graphite, but with a higher level of purity, which results in greater performance and longer life. Some advanced electrodes are also coated with special materials, such as silicon carbide, which further improves their durability and resistance to erosion.

One of the main benefits of using advanced electric arc furnace electrodes is increased productivity. The longer lifespan of these electrodes means that they can be used for longer periods without needing to be replaced. This reduces downtime, which can have a significant impact on the overall efficiency of the steelmaking process.

Another advantage of advanced electric arc furnace electrodes is improved energy efficiency. They have a lower electrical resistance than traditional electrodes, which means that they require less energy to operate. This can result in significant cost savings over time.

In addition to these benefits, advanced electric arc furnace electrodes can also improve the quality of the steel produced. They allow for more precise control over the melting process, which can result in a more uniform product. This is particularly important for industries that require high-quality steel for their products.

Finally, advanced electric arc furnace electrodes are also more environmentally friendly than traditional electrodes. They produce less waste and emissions, which can help to reduce the environmental impact of steel production.

RS Graphite Electrode Manufacturer noted, improving steelmaking processes is crucial for sustainability and profitability. Advanced electric arc furnace electrodes offer many benefits over traditional electrodes, including increased productivity, improved energy efficiency, better quality steel, and reduced environmental impact. As such, they are an important tool for any steelmaker looking to improve its processes and remain competitive in an ever-changing market.

Maintaining Consistent Electrode Consumption Rates in Electric Arc Furnaces

Electric arc furnaces (EAFs) are an essential component of modern steel production. They rely on a steady supply of electrodes to generate the heat necessary to melt and refine steel scrap. Electrodes are consumed during the EAF process, meaning they gradually burn away as they deliver electricity to the furnace. Maintaining consistent electrode consumption rates is critical to ensuring that the EAF operates efficiently and produces high-quality steel. According to the Rongsheng Group, the importance of electrode consumption rates in EAFs and discuss strategies for maintaining consistency.

Electrode consumption rates can vary depending on several factors, including the type of electrode, the steelmaking process, and the furnace’s operating conditions. Unpredictable consumption rates can cause issues such as inconsistent melting times and decreased furnace efficiency. Therefore, it is crucial to maintain a consistent consumption rate to achieve optimal steel production.

One strategy for maintaining consistent electrode consumption rates is to use high-quality electrodes. Quality electrodes can be made from various materials, such as graphite or carbon. They should be uniform in shape and size and have minimal impurities. High-quality electrodes have a predictable consumption rate, which helps to maintain consistent furnace operation.

Another strategy is to monitor the EAF process continuously. Monitoring allows operators to detect any changes in electrode consumption rates and take corrective action promptly. There are several monitoring methods available, such as thermal imaging and acoustic emission, which can detect changes in electrode consumption rates.

It is also important to ensure that the EAF is operating under the correct conditions. For instance, the furnace’s power settings, voltage, and current levels must be set correctly to achieve a consistent electrode consumption rate. Operators must monitor these settings regularly and adjust them as needed to maintain optimal electrode consumption rates.

Proper maintenance of the EAF and its components is also essential for consistent electrode consumption rates. Regular cleaning of the furnace’s interior and replacing worn or damaged parts, such as the furnace lid, can prevent electrode consumption from fluctuating.

Finally, proper training of personnel is critical. Steel production is a complex process, and operators must be trained to understand how to maintain a consistent electrode consumption rate. They must also know how to detect and troubleshoot issues that could cause fluctuations in electrode consumption rates.

In conclusion, maintaining consistent electrode consumption rates is critical for ensuring the efficient operation of an EAF and producing high-quality steel. Strategies for achieving this include using high-quality electrodes, monitoring the EAF process, setting correct operating conditions, maintaining the EAF, and providing proper training to personnel. By implementing these strategies, steel producers can achieve consistent and efficient steel production, which can lead to greater profitability and competitiveness. Rongsheng graphite electrodes manufacturer has rich experience in the production and sales of graphite electrodes. We can provide high-quality advanced UHP, HP, and RP graphite electrodes.