Category: Wiki

The wiki encyclopedic knowledge of graphite electrodes, from raw material selection to production and processing, graphite electrodes detection, packaging and shipping, etc.

Graphite Electrodes Wiki

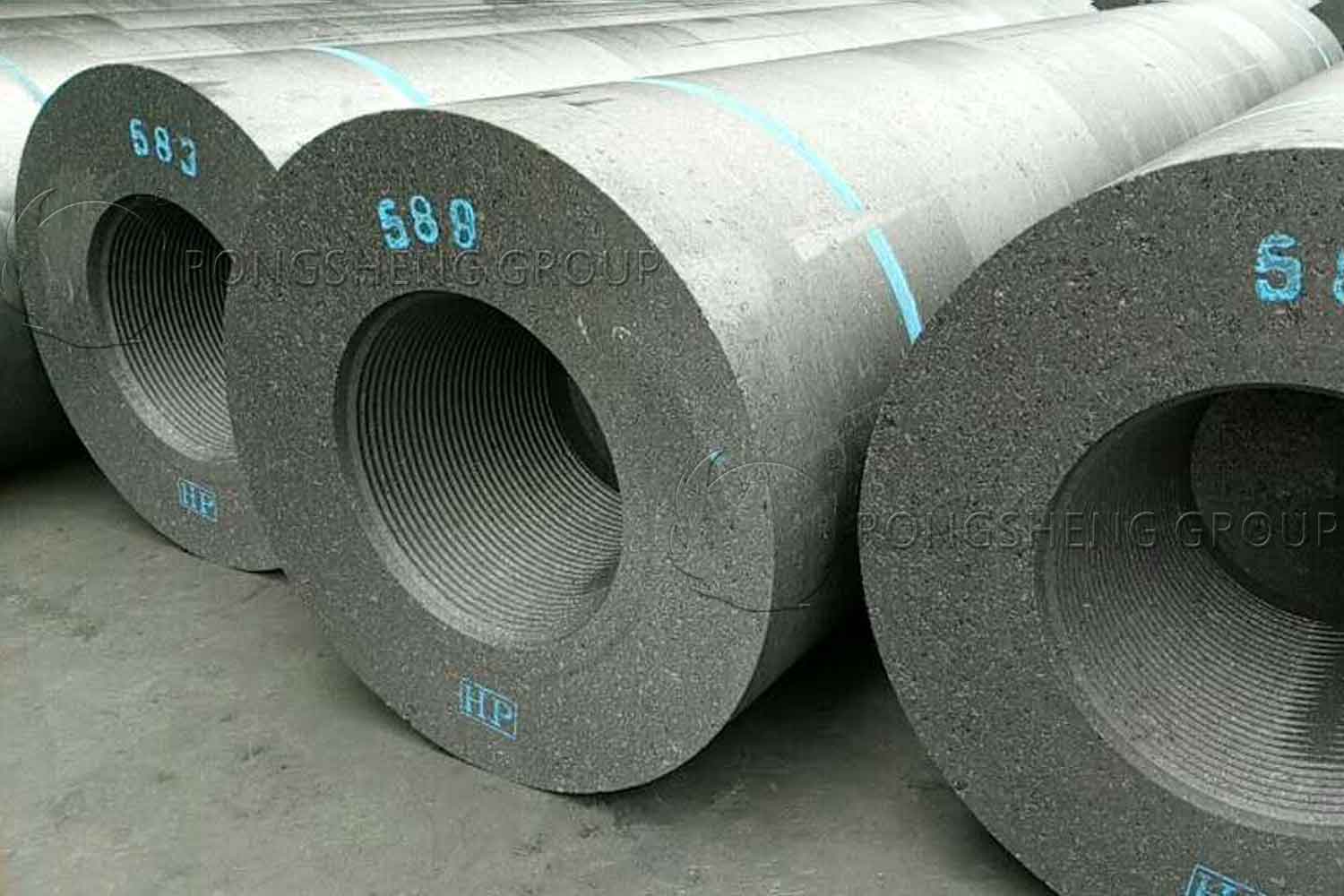

HP Graphite Electrodes with Nipples (Ф300 mm) – Efficiency Enhancing Steel Production in Electric Arc Furnaces

The steel industry has been revolutionized by advancements in electric arc furnace (EAF) technology. One of the key contributors to the efficiency and effectiveness of EAF operations is the graphite electrode, specifically the HP (High Power) variant. Among the most widely used is the HP Graphite Electrode with nipple Ф300 mm, a powerhouse of energy … Continue reading “HP Graphite Electrodes with Nipples (Ф300 mm) – Efficiency Enhancing Steel Production in Electric Arc Furnaces”

Why Choose UHP Grade Graphite Electrodes from Rongsheng Factory?

Understanding the Role of Ultra-High Power (UHP) Graphite Electrodes in Modern Industry. In the world of steel production and other high-temperature applications, graphite electrodes play a crucial role. These electrodes are indispensable in electric arc furnace (EAF) operations, where they serve as the conduits of electric current into the furnace, enabling the production of steel … Continue reading “Why Choose UHP Grade Graphite Electrodes from Rongsheng Factory?”

Impermeable Graphite with a Temperature Resistance of 1000 Degrees Celsius

Kyowa Carbon collaborated with the Osaka Industrial Technology Laboratory of the Institute of Industrial Technology to first develop impermeable graphite that can withstand a maximum operating temperature of 1000°C. The biggest feature of this graphite product is that it has a heat resistance three times that of current resin-impregnated carbon. The company has now built … Continue reading “Impermeable Graphite with a Temperature Resistance of 1000 Degrees Celsius”

Graphite Electrodes: Characteristics, Applications and Future Developments

Graphite electrode is an important carbon material that is widely used in industrial production and scientific research due to its unique physical and chemical properties. Rongsheng manufacturers can provide high-quality graphite electrode products. This article will delve into the characteristics, applications, and future development trends of graphite electrodes. Characteristics of graphite electrodes. Graphite electrodes are … Continue reading “Graphite Electrodes: Characteristics, Applications and Future Developments”

Effect of Roasting Process on Graphite Electrode Quality

Roasting is an important process for producing ultra-high-power graphite electrodes with excellent performance. By comparing the roasting furnace types and in-depth analysis of the heating mechanism of the green body during the roasting process. Understanding the effects of heating rate, binder pitch, temperature field and other factors on the quality of graphite electrodes can provide … Continue reading “Effect of Roasting Process on Graphite Electrode Quality”

Graphite Electrode: Introduction to Key Components of Electric Furnace Steelmaking

Graphite electrodes are an important part of the steelmaking industry as they play a vital role in the electric arc furnace (EAF) steelmaking process. These high-performance electrodes are made of graphite, a crystalline form of carbon, and are used as an electrically conductive material to transmit electrical energy to the electric arc furnace. Graphite electrodes … Continue reading “Graphite Electrode: Introduction to Key Components of Electric Furnace Steelmaking”

Influence of Splattering of Lengthwise Graphitization on UHP Graphite Electrodes

Inner string graphitization is a process in which the current directly passes through the furnace core composed of roasted products in series, and the roasted products are graphitized through the thermal effect of the current. In the process of graphitization and power transmission, the baked product is treated at a high temperature above 2400°C and … Continue reading “Influence of Splattering of Lengthwise Graphitization on UHP Graphite Electrodes”

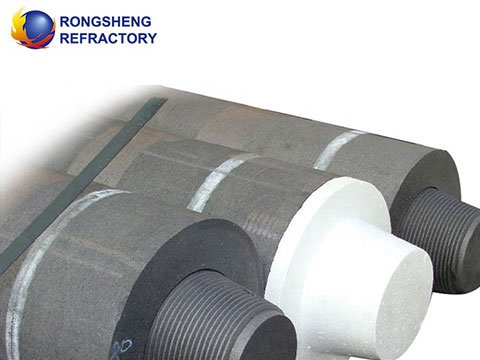

The Top Uses of Graphite Electrode Nipples in Industrial Applications

Graphite electrode nipples are an essential component in various industrial applications. These small, cylindrical pieces of graphite play a significant role in the production of steel, aluminum, and other metals. Graphite electrode nipples are widely used because of their exceptional thermal and electrical conductivity, high mechanical strength, and resistance to thermal shock. This essay discusses … Continue reading “The Top Uses of Graphite Electrode Nipples in Industrial Applications”

Maximizing Efficiency with Graphite Electrode 600 in Steel Production

The steel production industry is a highly competitive space where even minor improvements in efficiency can make a significant difference in profitability. One critical component in the steel production process is Graphite Electrode 600, which plays a vital role in determining efficiency and quality. In this essay, RS Graphite Electrodes Manufacturer will explore how Graphite … Continue reading “Maximizing Efficiency with Graphite Electrode 600 in Steel Production”

How to Tighten the Graphite Electrode Nipples?

The connection of graphite electrodes is realized through graphite electrode nipples. How to tighten the graphite electrode nipple? Graphite electrode manufacturers suggest that the torque required to screw the joint into the electrode screw hole to achieve a tight connection is well controlled. The contact resistance of the graphite electrode with a smooth surface varies … Continue reading “How to Tighten the Graphite Electrode Nipples?”

Price Quoting of Graphite Electrodes

If you want to know more about graphite electrode manufacturers, graphite electrode sellers, graphite electrode prices, high quality graphite electrode prices, please contact us.

- Email: info@graphelectrode.com

- WhatsApp: +86 185 3831 2977