In the world of high-temperature industries — from steel plants to glass and rock wool manufacturing — graphite electrodes are essential. But what makes a high-quality graphite electrode? The answer lies not just in the materials, but in the graphite electrode manufacturing process.

At Rongsheng, we believe that great products start with great processes. That’s why we have developed a rigorous, quality-focused manufacturing system that ensures every electrode we produce meets the demands of modern industry.

Let’s walk through each step of the process — and see why Rongsheng graphite electrodes are trusted by customers in over 120 countries.

Step 1: Raw Material Selection – The Foundation of Quality

The first step in the graphite electrode manufacturing process is choosing the right raw materials.

At Rongsheng, we use high-quality needle coke as the primary raw material. This material is known for its low ash content, high carbon purity, and excellent graphitization potential. Binder pitch, which acts as a glue to hold the coke particles together, is added in specific proportions.

By sourcing only stable, high-purity inputs, we ensure that the end product is consistent, conductive, and durable — even under extreme furnace conditions.

Step 2: Crushing, Screening & Dosing – Preparing for Precision

Next, the needle coke is crushed and screened into specific particle sizes. This allows us to create a consistent particle distribution, which affects the density, strength, and electrical conductivity of the electrode.

The ingredients are then dosed and mixed with the binder pitch according to a carefully calculated formula. The right balance of coarse and fine particles ensures strong mechanical properties and uniform performance across every graphite electrode.

Step 3: Kneading – Mixing It All Together

Once the ingredients are measured, they are heated and kneaded in large mixers. This step blends the pitch and coke together into a plastic, moldable compound. The temperature and mixing time must be controlled precisely to ensure even coating of the particles and optimal plasticity for the next step.

Step 4: Forming – Shaping the Electrode

After kneading, the mixture is transferred to extrusion presses. This is where the graphite electrode takes shape.

We produce electrodes in various diameters (from 100 mm up to 700 mm) and lengths (up to 2700 mm), depending on the client’s requirements. The mixture is shaped into cylindrical “green” electrodes and nipples (the connecting parts).

Forming requires great precision — a uniform and dense structure at this stage means better strength and electrical conductivity in the finished product.

Step 5: Baking – Carbonizing the Electrode

The formed electrodes are then slowly baked at temperatures around 800–1000°C. This process carbonizes the pitch binder and removes volatile matter, giving the electrode its strength and structural integrity.

This step can take several weeks, depending on the size and number of electrodes. Uniform baking is critical — any uneven heating can lead to internal stress or cracking, which shortens the electrode’s lifespan.

Step 6: Impregnation – Enhancing Density and Strength

After baking, the electrodes undergo pitch impregnation under high pressure and vacuum. This step fills any open pores with additional pitch, which is later baked again to further increase density and mechanical strength.

This step is especially important for HP graphite electrodes and UHP grades, where high current and mechanical stress require enhanced durability.

At Rongsheng, we may repeat the impregnation step more than once depending on the grade required — ensuring top-tier results for demanding applications.

Step 7: Graphitization – Turning Carbon into Graphite

Next comes the most energy-intensive step: graphitization.

In this process, the baked electrodes are heated to temperatures as high as 3000°C in a special graphitization furnace. At this extreme temperature, the carbon atoms in the electrode rearrange into a graphitic crystalline structure — increasing electrical conductivity and thermal resistance.

Graphitization is what transforms a carbon electrode into a true graphite electrode.

Step 8: Machining – Finishing to Precision

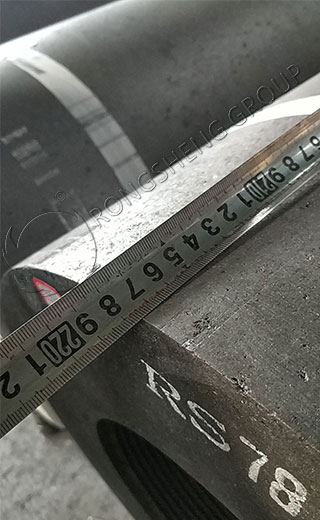

After graphitization, the electrodes and nipples are machined to exact dimensions. This includes:

-

- Cutting to length

- Turning the outer surface to precise diameter

- Drilling the socket for the nipple

- Machining the nipple threads

This ensures that each electrode has tight dimensional tolerances, perfect for reliable connection and smooth furnace performance.

Rongsheng uses CNC equipment to maintain accuracy and consistency in every batch.

Step 9: Quality Inspection – Ensuring Excellence

Before shipping, all Rongsheng graphite electrodes go through a strict inspection process, including:

-

- Electrical resistivity testing

- Bulk density and porosity testing

- Mechanical strength testing

- Surface and internal crack detection

Each electrode comes with a certificate of analysis. We maintain a product qualification rate over 98%, thanks to our rigorous in-house standards.

Step 10: Packaging & Delivery – Ready for Use

Finally, the graphite electrodes and nipples are carefully packaged and crated for safe transport. Our logistics team coordinates shipments to over 120 countries and regions, ensuring fast and reliable delivery.

Why Rongsheng’s Manufacturing Process Makes a Difference

Our customers care about performance, durability, and cost-efficiency — and so do we. Here’s what makes Rongsheng’s graphite electrode manufacturing process stand out:

-

- ✅ Custom Sizes Available: Tailored to your furnace’s needs

- ✅ Long Service Life: High strength, oxidation resistance, and structural integrity

- ✅ High Conductivity: Achieved through controlled graphitization

- ✅ Less Breakage: Thanks to precise machining and strong quality control

- ✅ Global Standards: ISO and CE-certified factory with customers worldwide

Applications Across Industries

While our focus today is on the graphite electrode manufacturing process, it’s worth noting that Rongsheng electrodes serve many sectors, including:

-

- Steelmaking (EAF & LF)

- Non-ferrous metallurgy

- Glass melting

- Rock wool production

- Chemical reactors

Wherever there’s extreme heat, graphite electrodes are needed — and Rongsheng delivers.

Call to Action

Are you looking for a trusted partner to supply high-quality graphite electrodes with a manufacturing process you can rely on? Rongsheng has you covered.

📩 Contact us for a free quote and consultation.

🌐 Visit our website to explore our RP, HP, and UHP graphite electrode products.

We’re ready to support your operation with custom solutions and proven quality.