Dia 550mm Graphite Electrode Manufacturer. In recent years, online searches for graphite electrodes have expanded beyond industrial buyers. Alongside professional queries, unexpected terms such as “graphite electrode minecraft” have begun appearing in search results. While this phrase originates from gaming communities, it highlights a broader issue: many people encounter graphite electrodes first online, without understanding their real industrial significance.

From the perspective of a professional dia 550mm graphite electrode manufacturer, graphite electrodes are not virtual tools or game materials. They are critical consumables used in some of the world’s most demanding high-temperature industries. This article explains what large-diameter graphite electrodes actually are, how graphite electrodes manufacturers produce them, where they are used, and why real-world performance differs greatly from simplified digital representations.

Understanding Dia 550mm Graphite Electrodes

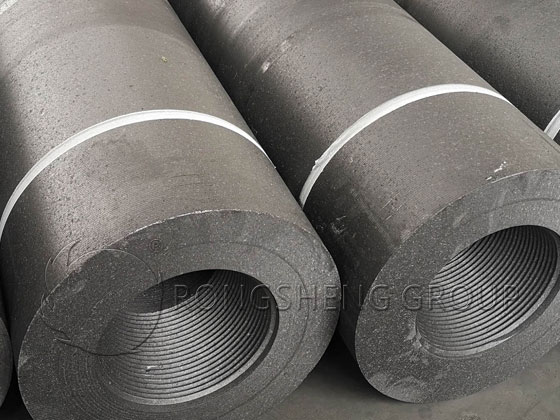

A 550mm graphite electrode belongs to the large-diameter category, typically used in high-capacity electric arc furnaces (EAFs). These furnaces operate under extreme electrical loads and thermal conditions, requiring electrodes with excellent conductivity, mechanical strength, and thermal shock resistance.

From a manufacturing standpoint, producing a 550mm electrode is significantly more complex than producing smaller sizes. Uniform density, internal structural stability, and precise machining become increasingly difficult as diameter increases. This is why not all graphite electrodes manufacturers are capable of producing consistent, high-quality dia 550mm graphite electrodes.

For steel plants and metallurgical enterprises, choosing the right dia 550mm graphite electrode manufacturer directly affects furnace stability, electrode consumption rate, and overall production efficiency.

Manufacturing Challenges Faced by Graphite Electrodes Manufacturers

Raw Material Control

Large-diameter electrodes require carefully selected raw materials. High-quality petroleum coke and needle coke are essential to achieve low electrical resistivity and strong thermal resistance. Any inconsistency in raw materials can lead to internal defects that become critical under ultra-high-power furnace conditions.

Density Uniformity

One of the most difficult tasks in producing dia 550mm graphite electrodes is maintaining uniform density throughout the electrode body. Uneven density may cause localized overheating, internal cracking, or premature electrode failure during operation.

High-Temperature Graphitization

Graphitization transforms carbon material into crystalline graphite at temperatures above 3000°C. For large electrodes, precise temperature control is vital. Professional graphite electrodes manufacturers invest heavily in advanced furnaces and process control to ensure complete and even graphitization.

Precision Machining

After graphitization, dia 550mm graphite electrodes require accurate machining, especially at the nipple connection. Any deviation in thread precision may affect electrical contact and mechanical stability during furnace operation.

Application Reality of Dia 550mm Graphite Electrodes

Electric Arc Furnace Steelmaking

In large EAFs, dia 550mm graphite electrodes are used to deliver massive electrical currents into the furnace. Their role is to generate a stable arc that melts scrap steel efficiently. Unlike simplified online depictions, real electrodes must endure continuous arc impact, oxidation, vibration, and mechanical stress.

Ultra-High-Power Furnace Operations

Many modern steel plants operate furnaces at higher power densities to shorten melting cycles. Large-diameter electrodes support this strategy by carrying higher current loads while maintaining arc stability and structural integrity.

Metallurgical and Industrial Furnaces

Beyond steelmaking, dia 550mm graphite electrodes are used in silicon metal furnaces, ferroalloy production, and other metallurgical processes requiring long-term high-temperature operation. These applications demand durability rather than the symbolic function often associated with “graphite electrode minecraft” searches.

Graphite Electrode Minecraft: Digital Curiosity vs. Industrial Reality

The keyword “graphite electrode minecraft” often reflects curiosity rather than industrial knowledge. In gaming environments, materials are simplified, instantly replaceable, and unaffected by real-world physics. In contrast, industrial graphite electrodes are engineered products where every parameter—resistivity, density, length, and diameter—directly impacts safety, efficiency, and cost.

From a manufacturer’s viewpoint, this contrast highlights the importance of education. Real graphite electrodes are not decorative or optional components. They are consumables that influence power consumption, furnace lifespan, and production stability.

Understanding this difference helps procurement teams, engineers, and even newcomers to the industry appreciate why professional graphite electrodes manufacturers invest so much in technology, testing, and quality control.

How a Dia 550mm Graphite Electrode Manufacturer Adds Value

Consistent Quality Output

Reliable manufacturers ensure that every batch of dia 550mm graphite electrodes meets strict internal standards. Consistency reduces operational risks and allows furnace operators to optimize power settings with confidence.

Technical Matching Support

Different furnaces require different electrode grades. Professional manufacturers provide technical guidance to help customers select suitable specifications based on transformer capacity, furnace design, and production targets.

Long-Term Cost Efficiency

Although large-diameter graphite electrodes represent a significant investment, high-quality products reduce breakage, lower consumption rates, and improve melting efficiency. Over time, this translates into lower cost per ton of output.

Global Supply Capability

Experienced graphite electrodes manufacturers maintain stable production capacity and international logistics systems, supporting customers across multiple regions and industries.

Rongsheng’s Manufacturing Perspective

As a professional dia 550mm graphite electrode manufacturer, Rongsheng integrates raw material control, advanced production equipment, and strict quality inspection into every stage of manufacturing. With a physical factory and long-term export experience, Rongsheng supplies graphite electrodes to steel, metallurgy, and industrial furnace operators worldwide.

Rather than focusing solely on size or grade, Rongsheng emphasizes performance reliability, service life, and customer support. This approach allows customers to achieve stable furnace operation even under increasingly demanding production conditions.

Industry Outlook for Large-Diameter Graphite Electrodes

As global steelmaking shifts toward higher efficiency and lower emissions, electric arc furnaces continue to expand. This trend increases demand for large-diameter graphite electrodes capable of supporting higher power input and shorter melting cycles.

At the same time, market awareness is expanding beyond traditional buyers, sometimes driven by unrelated search terms such as graphite electrode minecraft. This creates an opportunity for professional manufacturers to communicate real product value more clearly and differentiate industrial expertise from digital abstraction.

Conclusion

The role of a dia 550mm graphite electrode manufacturer goes far beyond supplying a large carbon product. It involves mastering complex production processes, ensuring consistent performance, and supporting customers in high-risk, high-temperature environments.

While terms like graphite electrode minecraft may attract casual attention, real industrial graphite electrodes are engineered tools that power modern steelmaking and metallurgical industries. Choosing experienced graphite electrodes manufacturers is essential for achieving safe operation, high productivity, and long-term cost control.

For steel plants, metallurgical enterprises, and procurement teams seeking a reliable dia 550mm graphite electrode manufacturer, Rongsheng offers proven manufacturing capability, stable supply, and professional technical support.

Contact Rongsheng today to discuss your furnace requirements and discover how high-quality graphite electrodes can improve efficiency, reliability, and overall production performance.