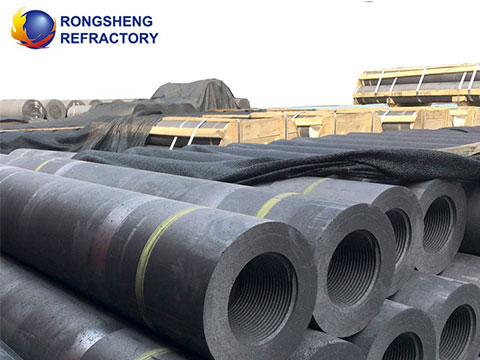

I wrote about Graphite Electrodes Raw Materials Select in my previous article. Today we will talk about choosing high-quality raw materials is a prerequisite for the production of UHP graphite electrodes.

Main Raw Material – Needle Coke

Needle coke must be used as the main raw material to produce ultra-high power graphite electrodes. There are two major types of needle coke, coal-based needle coke, and petroleum-based needle coke, which have a variety of quality specifications. The selection of needle focus depends on the electrode diameter. The larger the electrode diameter, the stricter the quality of needle focus. To study the quality of needle coke, first of all, we must understand the thermal expansion coefficient of the graphitized sample made from this needle coke. The second is the sulfur content and nitrogen content of the needle coke, as well as the actual particle size of the needle coke (the percentage of large particles), whether it can meet the needs of ingredients.

Although the price of coal-based needle coke is lower than that of petroleum-based needle coke, the graphitization performance of coal-based needle coke is also very good. However, the thermal expansion coefficient of coal-based needle coke is generally greater than that of petroleum-based needle coke, so coal-based needle coke is rarely used in large-diameter UHP graphite electrodes. As the carbon product industry in various countries in the world does not have a unified thermal expansion coefficient test method, Japan, Germany, and the United States each have their own test methods. Therefore, it is impossible to make a judgment by just looking at the sample or the data provided by the needle coke factory. It is necessary to collect needle coke samples from various companies and compare the results of the same method in the same laboratory.

Binder – Asphalt

Binder pitch mainly depends on three items: softening point, coking value, and bonding performance (β resin content). The softening point of the binder pitch used by the American Carbon Factory is about 110°C, and the test method is the air cube method. The softening point of the binder asphalt produced by Nippon Steel is 90±3°C and 96±3°C. The test method is the ring and ball method. The softening point of the binder asphalt produced by VFT AG in Germany is 109°C. The coking value of foreign binder asphalt is more than 55%, the beta resin content of Japanese asphalt is about 20%, and the American asphalt is slightly lower. Using this kind of pitch and controlling the proportion of pitch added during the batching, the HP graphite electrode body can reach the volume density requirement without dipping, and the UHP graphite electrode body only needs to be dipped once. Therefore, using high-quality asphalt with a slightly higher softening point and higher coking value as a binder for the production of HP and UHP graphite electrodes is a necessary means to achieve short-process production, that is, one less impregnation and one less roasting.

Impregnant – Pitch

As impregnant pitch, petroleum pitch is mostly used in the United States, and coal pitch is used in Japan and Germany. The common requirement is that the content of quinoline insolubles should be low, the lower the better. The general index is set below 0.5%, because quinoline insoluble matter affects the penetration of pitch into the micropores in the calcined electrode.

Additive

In the production of UHP graphite electrodes, it is also necessary to use appropriate additives to improve the performance of graphite electrodes.

(1) Iron oxide powder. The purpose is to increase the degree of graphitization and alleviate the “crystal swelling” during the graphitization process, which is more effective when using needle coke with higher sulfur content. When using internal tandem graphitization technology for large-diameter electrodes, the heating speed is extremely fast, and adding a small amount of iron oxide powder is beneficial to reduce the cracking waste during the graphitization process.

(2) Stearic acid. The purpose of adding is to reduce the softening point and viscosity of asphalt. This is useful when using asphalt with a higher softening point binder.

(3) Some foreign carbon factories add a small amount of mineral oil that acts as a plasticizer during the kneading process. The purpose of adding is to improve the plasticity of the electrode paste, reduce the friction force when the paste is extruded, and at the same time reduce the extrusion pressure, which is also conducive to improving the internal structure of the green electrode.

As explained in detail above, the selection of high-quality raw materials is a prerequisite for the production of UHP graphite electrodes. Therefore, it is also very important to choose a graphite electrode supplier with a reliable guarantee. Rongsheng Group provides customers with high-quality graphite electrodes. Get detailed information.