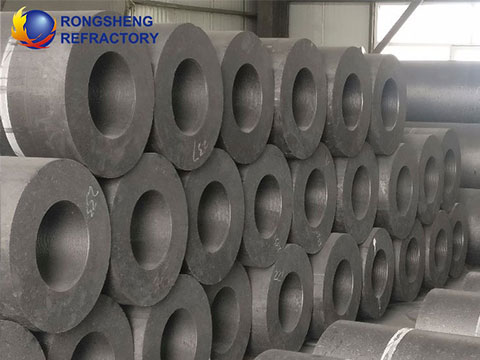

The graphite electrodes used in metallurgical enterprises are mainly made of petroleum coke and coal tar pitch. It has good high-temperature performance, low thermal expansion coefficient, lightweight, strong corrosion-resistance, easy processing, and excellent thermal shock resistance. But its most obvious defect at high temperature is that it is easily oxidized. The side oxidation of the UHP electrode is due to the oxygen and graphite in the furnace gas generating CO and CO2, accounting for 50% to 70% of the total consumption. Therefore, research on the High-Temperature Oxidation Resistance for Graphite Electrode is particularly important. In order to reduce the consumption of graphite electrodes, many scientific workers in the world have carried out research work on anti-oxidation, adding coatings, and changing the ratio of raw materials, and have achieved many research results.

Anti-Oxidation Method of Graphite Electrode

The oxidation protection of graphite electrodes is mainly through the following two ways. That is, at lower temperatures, matrix modification, and surface-active point passivation can be adopted to protect graphite materials. As the temperature rises, the coating method must be used to isolate the substrate from contact with oxygen to achieve the purpose of oxidation protection.

Impregnated Electrode

Graphite electrodes are limited by production conditions during the manufacturing process, and inevitably leave micropores inside the electrodes. Compared with other ordered carbon atoms, the electrode surface and pores have higher activity and are the active sites of oxidation of graphite electrodes. In the high-temperature state, it gradually expands to the inside, forming the oxidation consumption of the entire graphite electrode.

Impregnated electrode technology has the characteristics of low investment, low cost, simple process, and strong adaptability. It is an effective way to reduce graphite electrode consumption and has obvious economic benefits.

Coated Electrode

Coating system requirements. Anti-oxidation coating is the most effective and main means of anti-oxidation of the graphite electrode. It can greatly increase the use temperature of the graphite electrode in an oxidizing environment. Its basic function is to isolate the matrix material from the oxidizing environment.

The comprehensive performance of the graphite electrode coating cannot be achieved by a single material, and a multi-functional gradient coating must be selected. Each of these layers has its own unique functions and uses, and the composite coating as a whole realizes anti-oxidation. Generally speaking, a complete coating system should contain at least three layers of the oxygen barrier layer, functional active layer or self-healing layer, adhesive layer. When designing, they must comprehensively consider the matching of the thermal expansion coefficients, chemical compatibility, and overall coordination between the layers.

The high-temperature anti-oxidation coating of graphite electrodes is not enough for a substance, and a single-layer coating cannot play an effective anti-oxidation role. From the RS graphite electrode manufacturer, The development direction of the coating system is multifunctional gradient composite coating. In the manufacturing method of coating, in addition to the traditional CVD method and solid infiltration method. Plasma spraying technology has been introduced at home and abroad and has received good results.