Based on the different standards of various graphite electrode manufacturers, the grades of graphite electrodes are generally as follows:

- Regular graphite electrode (RP)

- Impregnated graphite electrode

- High Power Graphite Electrode (HP)

- SHP Graphite Electrode (SHP)

- Ultra High Power Graphite Electrode (UHP)

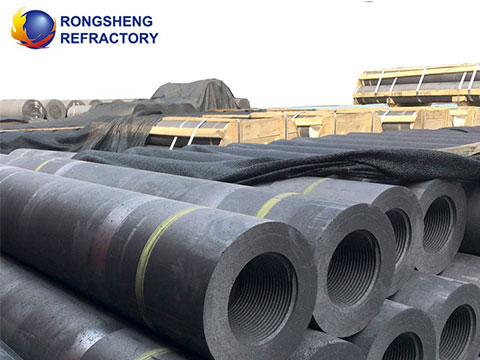

The graphite electrodes of Rongsheng graphite electrode manufacturer are equipped with tapered joints, which comply with national standards and international standards such as NEMA CG1, IEC 60239, JIS R7201 and so on.

The use and performance of graphite electrodes:

- Used in steelmaking electric arc furnace, refining furnace, as conductive electrode;

- Used in industrial silicon furnace, yellow phosphorus furnace, corundum furnace, etc., as conductive electrode.

Performance of Graphite Electrode:

- Good conductivity

- Strong thermal shock resistance

- High mechanical strength

Applications of graphite electrodes

In actual use, the specifications and grades of graphite electrodes should be selected according to the specific furnace conditions. The first factor is the maximum current intensity. At the same time, the influence of other factors, such as the characteristics of the electric furnace, the type of charge, the smelting time, the amount of oxygen blowing, the mechanical requirements, and the steelmaking process system, must also be considered.

Generally, the physical and chemical indicators of most grade graphite electrodes have been standardized. However, in the process of use, the influence of temperature on some indicators must be considered sometimes.

Precautions when using graphite electrodes:

● According to the capacity of the electric furnace and the load of the transformer, select the grade and diameter of the electrode appropriately.

● When charging the electric furnace, a large piece of charge should be installed on the bottom of the furnace to prevent the charge from falling and hitting the electrode. During the smelting process, a large amount of non-conductive objects, such as lime, should be prevented from accumulating directly under the electrode, otherwise it will affect the electrode current, and even cause the electrode to break.

● Pay attention to the position of the furnace cover. If the furnace cover is misaligned, the furnace cover will be scratched when the electrode is raised and lowered, resulting in electrode damage.

● When connecting the electrodes, if there is any defect in the connector plugs, replace them and then connect them.

● After the electrode is connected, if there is a gap on the connection surface, be sure to find out the cause. Use after the gap is eliminated.

● The electrode must be used vertically.

● The electrode holder should be clamped between the upper and lower cords of the top electrode. It is strictly forbidden to sandwich the electrode in the cord (joint hole) and the middle electrode, otherwise the electrode column may be easily broken.

● Because the raw materials and production processes of different manufacturers may be different, the physical and chemical properties of the electrodes are also different. It is recommended that the connectors and electrodes produced by different manufacturers not be used in series.