With the development of science and technology, the function of the EAF furnace is more refined (melting furnace and refining furnace), and the electric furnace is also equipped with a large-capacity transformer, and the electric furnace steelmaking has become larger. At the same time, graphite electrodes were used as conductive materials and were introduced into the electric steelmaking industry. The graphite electrode uses is also obvious, providing a heat source for steelmaking furnaces.

Graphite Electrode Uses

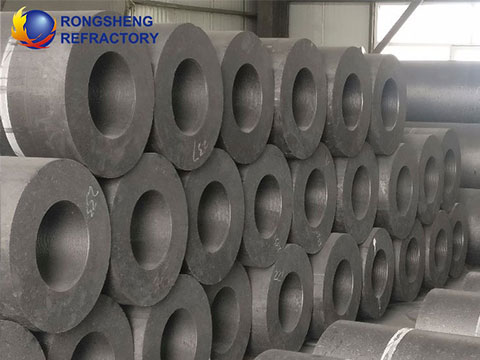

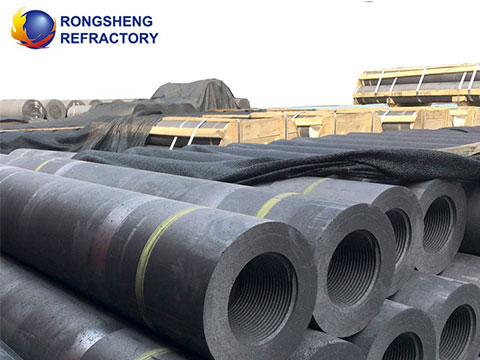

Graphite electrodes uses as a conductive material in a variety of electric furnace types.

(1) For Electric Arc Furnace

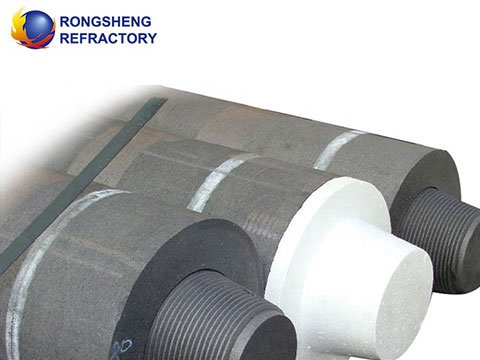

Graphite electrodes are mainly used in electric furnace steelmaking. EAF steelmaking uses a graphite electrode to introduce a current into the furnace. A strong current generates an arc discharge through the gas at the lower end of the electrode, and the heat generated by the arc is used for smelting. According to the size of the electric furnace, graphite electrodes of different diameters are used. In order to continuously use the electrodes, the electrodes are connected by electrode nipples. The graphite electrode for steelmaking accounts for about 70-80% of the total amount of graphite electrode. With the increase in the size of electric furnaces, the ultra-high power graphite electrode uses is increasing.

(2) Used in Mine Electric Furnace

Graphite electrode ore electric furnace is mainly used for the production of ferroalloys, pure silicon, yellow phosphorus, matte and calcium carbide. It is characterized in that the lower part of the conductive electrode is buried in the charge, so the arc between the electric plate and the charge generates heat, and the current Heat is also generated by the electrical resistance of the charge as it passes through the charge. About 1,500 tons of graphite electrode is consumed per ton of silicon, and about 40 kg of graphite electrode is consumed per ton of yellow phosphorus.

(3) For Resistance Furnace

The graphitization furnace for producing graphite products, the melting furnace for melting glass, and the electric furnace for producing silicon carbide are all electric resistance furnaces, and the materials contained in the furnace are both heating resistors and heated objects. Usually, the graphite electrode for electricity conduction is inserted into the furnace wall at the end of the hearth, so that the conductive electrode is not continuously consumed.

RS Graphite Electrode Supplier

As a graphite electrode supplier, RS graphite electrode manufacturers provide customers with RP, HP, UHP graphite electrodes, and supporting graphite electrode nipples. For graphite electrode uses, the quality of our graphite electrodes is guaranteed and has been well received by our customers. To get the latest graphite electrode prices, please contact us!