Category: Wiki

The wiki encyclopedic knowledge of graphite electrodes, from raw material selection to production and processing, graphite electrodes detection, packaging and shipping, etc.

Graphite Electrodes Wiki

Spot Prices of UHP 600mm Graphite Electrodes

The global demand for Ultra-High Power (UHP) graphite electrodes, particularly the 600mm diameter variant, remains strong due to their critical role in electric arc furnace (EAF) steelmaking. As a leading manufacturer, Rongsheng Graphite closely monitors spot prices, which fluctuate based on raw material costs, supply chain dynamics, and shifts in steel production. This blog examines … Continue reading “Spot Prices of UHP 600mm Graphite Electrodes”

12-Inch Regular Power Graphite Electrodes Specifications & Benefits for EAF Operations

UHP & Regular Power Graphite Electrodes can Enhance Efficiency in Steelmaking. In the steel and metallurgical industries, the quality of graphite electrodes plays a crucial role in electric arc furnace (EAF) operations. As a leading graphite electrode manufacturer, Rongsheng specializes in producing Ultra High Power (UHP) graphite electrodes with respective nipples and Regular Power (RP) … Continue reading “12-Inch Regular Power Graphite Electrodes Specifications & Benefits for EAF Operations”

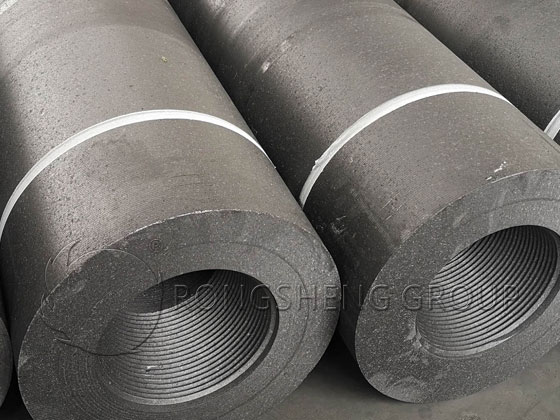

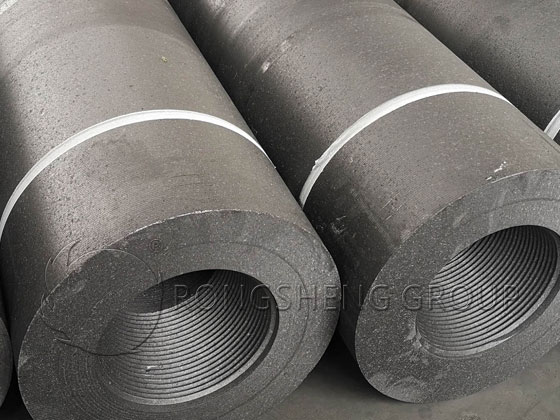

Graphite Electrodes with Nipples for EAF and LRF Applications

Enhancing EAF and LRF Efficiency with Rongsheng’s Graphite Electrodes with Nipples. In the world of industrial manufacturing, the efficiency and reliability of electric arc furnaces (EAF) and ladle refining furnaces (LRF) are critical to achieving optimal production outcomes. At the heart of these operations lies a crucial component: the graphite electrode. Specifically, Graphite Electrode with … Continue reading “Graphite Electrodes with Nipples for EAF and LRF Applications”

The Ultimate Guide to Buying Graphite Electrodes for Yellow Phosphorus Manufacturing

In the world of industrial manufacturing, the production of yellow phosphorus stands out as a highly specialized and demanding process. This critical chemical compound is widely used in producing fertilizers, pesticides, and even semiconductors. However, the efficiency and success of yellow phosphorus manufacturing heavily depend on the quality of the equipment used, particularly graphite electrodes. … Continue reading “The Ultimate Guide to Buying Graphite Electrodes for Yellow Phosphorus Manufacturing”

Why Choose Rongsheng for UHP Graphite Electrodes: Comprehensive Specifications and Benefits

In the rapidly evolving steelmaking and metallurgical industries, the need for reliable, high-performance materials has never been greater. Among the most critical components in electric arc furnaces (EAF) are ultra-high-power (UHP) graphite electrodes. Rongsheng Graphite Electrode Manufacturer is proud to offer a range of UHP electrodes, including UHP700, UHP500, and UHP300, designed to meet the … Continue reading “Why Choose Rongsheng for UHP Graphite Electrodes: Comprehensive Specifications and Benefits”

How HP and UHP Graphite Electrodes with Nipple Dia 200 x 1800mm Power High-Temperature Industrial Applications

Rongsheng HP and UHP Graphite Electrodes are for sale. Graphite electrodes play a crucial role in numerous high-temperature industrial processes, particularly in electric arc furnaces (EAFs) and ladle furnaces (LFs). As one of the leading providers of high-performance refractory products, Rongsheng Graphite Electrode Manufacturer supplies robust and durable graphite electrodes tailored for industrial applications requiring … Continue reading “How HP and UHP Graphite Electrodes with Nipple Dia 200 x 1800mm Power High-Temperature Industrial Applications”

The Role of UHP Graphite Electrodes (600mm) in High-Performance Steelmaking

Introduction to UHP Graphite Electrodes. As industries push towards higher efficiency and sustainability, ultra-high-power (UHP) graphite electrodes have emerged as essential components in the steelmaking process, particularly in electric arc furnaces (EAFs). UHP graphite electrodes are designed to handle extremely high electrical currents and temperatures, making them ideal for intensive, high-output steel production environments. Among … Continue reading “The Role of UHP Graphite Electrodes (600mm) in High-Performance Steelmaking”

Diameter 352-357mm, Length 1800 (±100)mm: HP Graphite Electrodes for Steelmaking Applications

The Role of High-Power Graphite Electrodes in Modern Steelmaking. High-power (HP) graphite electrodes have become a cornerstone of steel production, especially in electric arc furnace (EAF) technology, which dominates modern steelmaking due to its efficiency and environmental benefits. With the ability to withstand intense temperatures and electrical currents, these electrodes play a pivotal role in … Continue reading “Diameter 352-357mm, Length 1800 (±100)mm: HP Graphite Electrodes for Steelmaking Applications”

UHP Graphite Electrodes: UHP 600, UHP 300, and UHP 200

UHP Graphite Electrodes: Powering the Future of Steel Production. In the ever-evolving steel industry, efficient and high-performance materials are essential for keeping production costs low while maintaining high output quality. Ultra-High Power (UHP) graphite electrodes are a crucial element in electric arc furnace (EAF) steelmaking. These electrodes are designed to handle the intense electrical currents … Continue reading “UHP Graphite Electrodes: UHP 600, UHP 300, and UHP 200”

Graphite Electrodes from Fine Coke: Graphite Electrodes HP Grade 400 and 300 Diameters

The Role of HP Grade Graphite Electrodes from Fine Coke in Steelmaking. In the steelmaking industry, the electric arc furnace (EAF) process is widely used to produce high-quality steel. Central to the efficient functioning of these furnaces are graphite electrodes, which facilitate the melting of scrap steel through high-temperature electric arcs. Among the various types … Continue reading “Graphite Electrodes from Fine Coke: Graphite Electrodes HP Grade 400 and 300 Diameters”

Price Quoting of Graphite Electrodes

If you want to know more about graphite electrode manufacturers, graphite electrode sellers, graphite electrode prices, high quality graphite electrode prices, please contact us.

- Email: info@graphelectrode.com

- WhatsApp: +86 185 3831 2977