Graphite Electrode Application, in electric arc furnaces steel production, graphite electrodes are commonly used. They are currently the best products be used, and that have the high levels of electrical conductivity and the capability of maintaining the extremely excessive levels of heat generated in this working environment. Graphite electrodes are also used to refine metallic in ladle furnaces and in other smelting processes.

According to the difference in power of the electricity served, RS graphite electrodes manufacturer uses different refractory raw materials and production technology, producing the graphite electrodes can be divided into ordinary power graphite electrodes, high power graphite electrode, ultra-high power graphite electrodes.

RS Graphite electrode has good electrical properties and chemical stability. In details, all kinds of the graphite electrode has advantages of high mechanical strength, low impurity content and good vibration resistance. Graphite electrodes are good conductors of heat and electricity.

In the graphite electrode application side, graphite electrode is widely used in:

- steelmaking electric furnace,

- refining furnaces,

- submerged arc furnaces,

- and other smelting furnaces that produce high temperatures by electric arc.

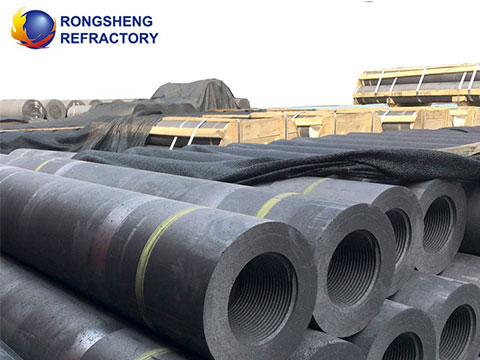

RS graphite electrode is made from the domestic first petroleum coke and high quality needle coke and widely used in the electric furnaces refractories for production of alloy steels, metal and other refractory nonmetallic materials, etc. Graphite Electrode Application. The graphite electrodes include rp, hp graphite electrode, super high power, uhp and square electrode. The range of diameters covers from 200mm to 700mm.

Welcome to RS, getting the details of the graphite electrodes info and the graphite electrode price. RS can confirm the quality and the quantity. For more: info@graphelectrode.com .