Rongsheng Group — One of the Worldwide Leading Graphite Electrode Manufacturers.

Rongsheng Group as a graphite electrode manufacturer, owns an in-depth raw material, production line, and engineering expertise, experienced applications on steelmaking furnaces, a comprehensive graphite based product portfolio, such as (RP, hp, UHP) graphite electrode, graphite electrodes nipples, graphite block, graphite powder, graphite tile, graphite crucible, graphite mould, carbon raiser, etc.

More >

Rongsheng Graphite Electrodes

Rongsheng graphite electrodes can be divided into UHP, HP, and RP according to the power used.

Graphite Electrode Classification

According to power usage, graphite electrodes can be classified into UHP/HP/RP.

LEARN MOREGraphite Electrode Nipple

The screw threads on the nipple surface, and the nipple pin through it.

LEARN MOREGraphite Electrode Body

There are two warning lines on the surface of the graphite electrode body closed to the ends. The screw threads are in each hole at the end.

LEARN MOREPrice Quoting of Graphite Electrodes

Know more about graphite electrode manufacturers, graphite electrode sellers, graphite electrode prices, high-quality graphite electrode prices, and for the price quoting of graphite electrodes, please contact us.

- Or mail to sales manager, Email: info@graphelectrode.com

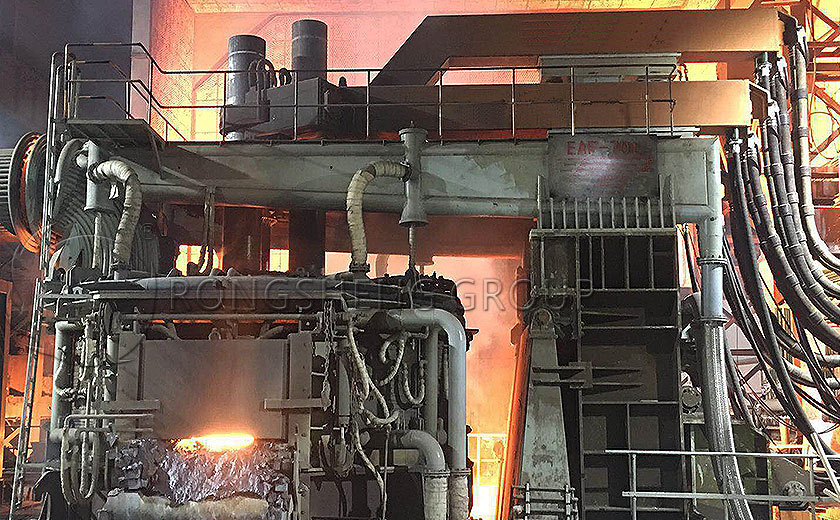

Application of Graphite Electrode

Graphite electrode as a major conduction material is mainly applied for the electric furnace smelting industry. Graphite electrodes are used in EAF, Submerged-arc furnace, Electric resistance furnace, etc.

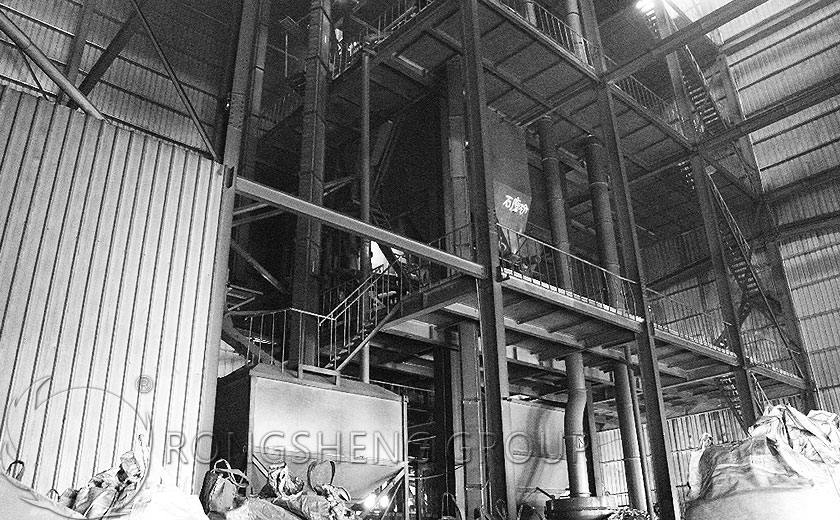

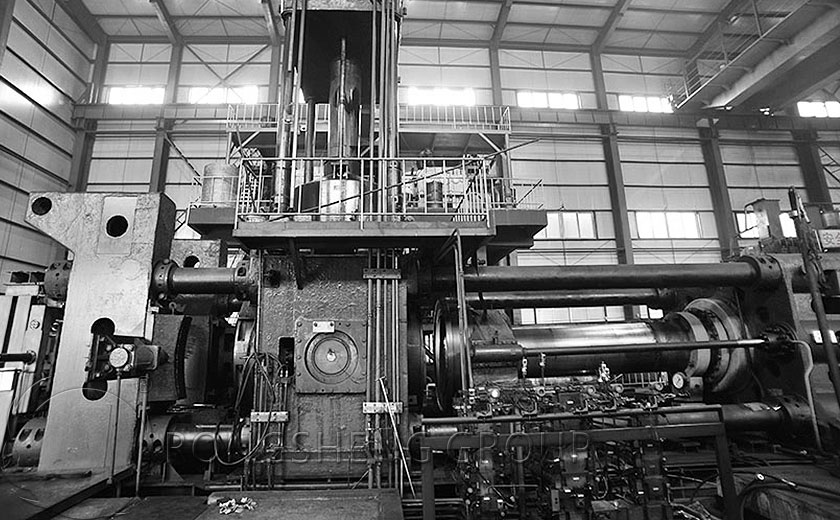

The Manufacturing Process of Graphite Electrodes

The manufacturing process of graphite electrodes is from the preparation of the raw materials (a series of crushing, calcining, milling, sieving, and finally mixed together) to the kneading and pressing, and then baking, Impregnation, graphitizing, machining, and finally the graphite electrode products. MORE >

The manufacturing process of graphite electrodes in Rongsheng. Every step is rigorously inspected to ensure the production of high-quality graphite electrode products.