Category: Wiki

The wiki encyclopedic knowledge of graphite electrodes, from raw material selection to production and processing, graphite electrodes detection, packaging and shipping, etc.

Graphite Electrodes Wiki

What Is a Graphite Electrode? Understanding Electric Arc Furnace Electrodes from Rongsheng

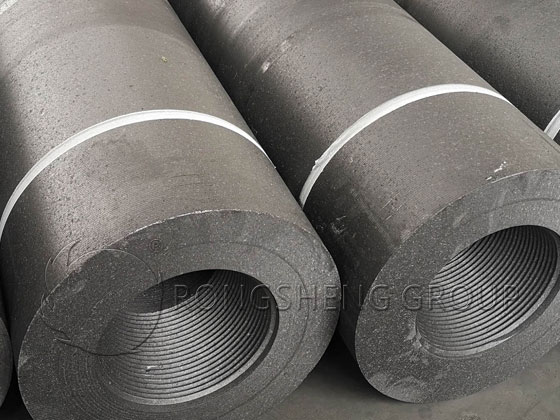

What Is a Graphite Electrode – The Core of Electric Arc Furnace Steelmaking. In the world of modern metallurgy, few materials are as critical as the graphite electrode. These cylindrical carbon products serve as the vital conductors in electric arc furnaces (EAFs), where scrap metal and other raw materials are melted to produce high-quality steel … Continue reading “What Is a Graphite Electrode? Understanding Electric Arc Furnace Electrodes from Rongsheng”

How Rongsheng Converts Graphite Raw Materials into High-Performance EAF Electrodes

Rongsheng’s Graphite Electrode Factory – Precision Built for High-Temperature Industry. Behind every efficient electric arc furnace (EAF) stands an electrode capable of conducting immense electrical energy and withstanding extreme heat. These electrodes are the core of modern steelmaking and metallurgical processes, where performance and stability determine production success. At the heart of this precision lies … Continue reading “How Rongsheng Converts Graphite Raw Materials into High-Performance EAF Electrodes”

Trusted Graphite Electrode Producers for Modern Steelmaking and Metallurgy

Rongsheng – A Leading Bulk Graphite Electrode Manufacturer for Global Industry. In the world of high-temperature industrial production, few materials are as essential as graphite electrodes. They are the conductors that transform electrical energy into heat, enabling steelmaking, alloy refining, and advanced material processing. Behind every stable furnace operation stands a dependable producer capable of … Continue reading “Trusted Graphite Electrode Producers for Modern Steelmaking and Metallurgy”

UHP Graphite Electrodes and Electric Arc Furnace Advantages – Efficiency Redefined by Rongsheng

Rongsheng’s UHP Graphite Electrodes – Powering the Future of Electric Arc Furnace Steelmaking. Electric arc furnaces (EAFs) represent the future of modern steel production — efficient, flexible, and environmentally responsible. At the heart of every EAF lies the electric arc furnace electrode, the essential conductor that transforms electrical energy into heat exceeding 3000°C, melting scrap … Continue reading “UHP Graphite Electrodes and Electric Arc Furnace Advantages – Efficiency Redefined by Rongsheng”

High-Performance Graphite Electrodes and Nipples for Modern Furnaces

Rongsheng – A Trusted Global Graphite Electrode Supplier. As steelmaking, metallurgy, and high-temperature industries evolve, demand grows for durable, energy-efficient, and stable electrode materials. At the core of these processes lies the graphite electrode, a material capable of conducting intense electrical current and sustaining temperatures over 3000°C. Rongsheng, an internationally recognized graphite electrode supplier, provides … Continue reading “High-Performance Graphite Electrodes and Nipples for Modern Furnaces”

From EAF Design to Furnace Operation – The Role of Rongsheng Arc Furnace Electrodes

Optimizing EAF Efficiency with Rongsheng Arc Furnace Electrodes. In modern steelmaking, electric arc furnaces (EAFs) play a vital role in producing high-quality steel with energy efficiency and environmental responsibility. The success of every EAF operation depends not only on precise EAF calculation but also on the performance of its arc furnace electrodes — the key … Continue reading “From EAF Design to Furnace Operation – The Role of Rongsheng Arc Furnace Electrodes”

Arc Furnace Electrodes from a Trusted Graphite Electrode Manufacturer

Arc Furnace Electrodes from Rongsheng – Built for Demanding Industries. In steel plants, glass factories, and other high-temperature industries, arc furnace electrodes are the workhorses that keep production running. They conduct massive amounts of electricity into furnaces, creating the heat necessary to melt and refine raw materials. Choosing the right electrodes isn’t just a technical … Continue reading “Arc Furnace Electrodes from a Trusted Graphite Electrode Manufacturer”

How Rongsheng Ensures Quality in the Graphite Electrode Manufacturing Process

In the world of high-temperature industries — from steel plants to glass and rock wool manufacturing — graphite electrodes are essential. But what makes a high-quality graphite electrode? The answer lies not just in the materials, but in the graphite electrode manufacturing process. At Rongsheng, we believe that great products start with great processes. That’s … Continue reading “How Rongsheng Ensures Quality in the Graphite Electrode Manufacturing Process”

Rongsheng Graphite Electrodes: Quality RP and HP Grades for Industrial Applications

Graphite electrodes play a crucial role in modern high-temperature industries. Whether you’re melting scrap steel in an electric arc furnace or operating a refining furnace for high-grade alloys, the performance of your graphite electrode matters. At Rongsheng, we offer a full range of reliable, customizable electrodes, including RP graphite electrodes and HP graphite electrodes, designed … Continue reading “Rongsheng Graphite Electrodes: Quality RP and HP Grades for Industrial Applications”

Why Rongsheng Graphite Electrodes Deliver Reliability?

The Unsung Hero of Modern Steelmaking. Graphite electrodes are the lifeline of electric arc furnaces (EAFs), transforming scrap metal into molten steel at temperatures exceeding 3,000°C. For steel plants, rock wool producers, and glass manufacturers, electrode failure means costly downtime. Rongsheng Group solves this with electrodes engineered for extreme resilience, backed by rigorous quality control … Continue reading “Why Rongsheng Graphite Electrodes Deliver Reliability?”

Price Quoting of Graphite Electrodes

If you want to know more about graphite electrode manufacturers, graphite electrode sellers, graphite electrode prices, high quality graphite electrode prices, please contact us.

- Email: info@graphelectrode.com

- WhatsApp: +86 185 3831 2977