Category: Wiki

The wiki encyclopedic knowledge of graphite electrodes, from raw material selection to production and processing, graphite electrodes detection, packaging and shipping, etc.

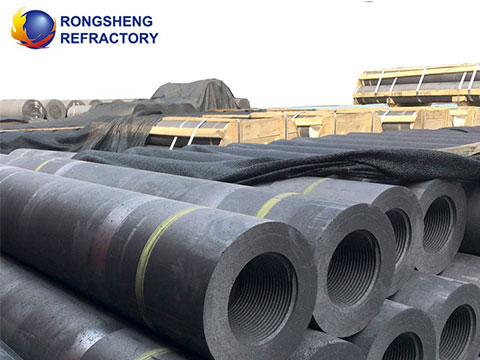

Graphite Electrodes Wiki

Application of Graphite Electrode in Steelmaking Electric Arc Furnace

Graphite electrodes are mainly used as conductive materials in electric smelting furnaces. Compared with other conductive materials, the biggest advantage of graphite electrode material is that it has good electrical and thermal conductivity and better toughness, can accept the impact of larger current and does not soften or melt at high temperatures. It is used … Continue reading “Application of Graphite Electrode in Steelmaking Electric Arc Furnace”

Influence of Temperature Distribution of Graphite Electrode Nipple on Thermal Stress

The nipple connection area in the graphite electrode column is a common part of fracture, and it is also a complex area with large electrical, thermal, and mechanical loads. There is large thermal stress in this area, so it is also a part that needs to be studied. Experiment on the Influence of Temperature Distribution … Continue reading “Influence of Temperature Distribution of Graphite Electrode Nipple on Thermal Stress”

Discussion on Vibration Forming Method to Produce Graphite Electrode

There are generally three molding methods used in the carbon industry, namely compression molding, extrusion molding, and vibration molding methods. Among them, the compression molding method is low due to labor productivity. At present, except for a small number of products with special requirements that use this molding method, the molding process in the carbon … Continue reading “Discussion on Vibration Forming Method to Produce Graphite Electrode”

Performance Index of Graphite Electrode Body and Nipple

The graphite electrode body needs the graphite electrode nipple to connect them one by one in series. Therefore, they also have certain connections and differences in performance indicators. The Performance Index Difference of Graphite Electrode Body and Nipple (1) Resistivity. The resistivity of ordinary power graphite electrode is not more than 8.5μΩ·m, 9.0μΩ·m, 10.0μΩ·m, and 10.5μΩ·m, and the … Continue reading “Performance Index of Graphite Electrode Body and Nipple”

What are the Differences of the Electrodes for Submerged Arc Furnaces?

The role of the electrode is to conduct electricity and convert electrical energy into heat. Electrodes are divided into three types: carbon electrodes, graphite electrodes, and self-baking electrodes according to their use and production process. In submerged arc furnaces, self-baking electrodes are mainly used, but when producing ferroalloy products with lower carbon content, such as … Continue reading “What are the Differences of the Electrodes for Submerged Arc Furnaces?”

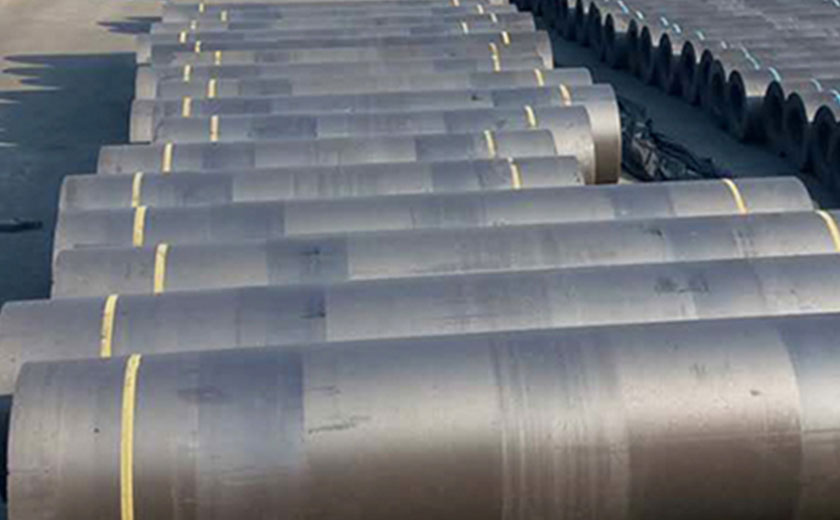

Large Diameter Graphite Electrodes in DC Arc Furnace

The physical performance requirements of large-scale, UHP graphite electrodes, with the introduction and continuous expansion of DC electric arc furnaces in my country, are of great significance for the best use of electric arc furnaces and reducing electrode consumption. Therefore, in order to promote the development of the electric furnace steelmaking industry, it is also … Continue reading “Large Diameter Graphite Electrodes in DC Arc Furnace”

Configuration of Graphite Electrodes for Steelmaking Electric Arc Furnaces

In the configuration of Graphite Electrodes for Steelmaking Electric Arc Furnaces, it is necessary to follow the basic principle of “normal power electric furnaces with ordinary power graphite electrodes, high-power electric furnaces with high-power graphite electrodes, and ultra-high-power electric furnaces with ultra-high-power graphite electrodes“. Configuration Scheme of the Graphite Electrode for AC Steelmaking Electric Arc … Continue reading “Configuration of Graphite Electrodes for Steelmaking Electric Arc Furnaces”

Prerequisite for the Production of UHP Graphite Electrodes

I wrote about Graphite Electrodes Raw Materials Select in my previous article. Today we will talk about choosing high-quality raw materials is a prerequisite for the production of UHP graphite electrodes. Main Raw Material – Needle Coke Needle coke must be used as the main raw material to produce ultra-high power graphite electrodes. There are … Continue reading “Prerequisite for the Production of UHP Graphite Electrodes”

Rongsheng RP Graphite Electrodes for Sale in South Africa

Graphite electrode is a conductor that releases electrical energy in the form of an electric arc to heat and melt the charge. The main raw material for graphite electrode production is petroleum coke. Ordinary power graphite electrodes can be added with a small amount of pitch coke. The sulfur content of petroleum coke and pitch … Continue reading “Rongsheng RP Graphite Electrodes for Sale in South Africa”

Effect of Baking Process on the Quality of Graphite Electrodes

Baking is an important process for producing uhp graphite electrodes with excellent performance. Factors such as heating rate, binder pitch, and temperature field have an impact on the quality of graphite electrodes during the baking process. It can provide a reference for the production of high-quality graphite electrodes. Ultra-high Power Graphite Electrode The ultra-high power … Continue reading “Effect of Baking Process on the Quality of Graphite Electrodes”

Price Quoting of Graphite Electrodes

If you want to know more about graphite electrode manufacturers, graphite electrode sellers, graphite electrode prices, high quality graphite electrode prices, please contact us.

- Email: info@graphelectrode.com

- WhatsApp: +86 185 3831 2977