The connection of graphite electrodes is realized through graphite electrode nipples. How to tighten the graphite electrode nipple? Graphite electrode manufacturers suggest that the torque required to screw the joint into the electrode screw hole to achieve a tight connection is well controlled.

The contact resistance of the graphite electrode with a smooth surface varies with the applied pressure. As the pressure increases, the contact resistance decreases. In order to reduce the contact resistance of the contact parts during electrode connection as much as possible, in addition to the two important conditions of graphite electrode material and processing accuracy, which must meet the technical standards, sufficient tightening torque must be applied when connecting electrodes in steelworks. If the tightening torque is insufficient when connecting, the contact resistance of the contact surface will increase significantly. Even high-quality electrodes will have redness and accelerated oxidation at the contact surface. Or loosening occurs in a strong vibration, increasing the chance of nipple breaking. The larger the electrode specification, the greater the tightening torque required. But the tightening torque is not as big as possible, but to reach a certain torque.

There are two main factors that affect the tightening torque not reaching the specified level. (1) The electrode processing quality is not good. If the processing surface is rough or the clearance of the thread is not well matched, it is difficult to screw into the joint, or it is still loose when it is screwed to the bottom of the screw hole, so it cannot be tightened. (2) The steel mill operator did not tighten the electrode and the joint when adding the new graphite electrode nipple, that is, the required tightening torque was not reached. In order to ensure that the required tightening torque can be achieved when connecting electrodes with different specifications, you can choose to use a graphite electrode wrench.

When tightening graphite electrodes in the smelting industry in some areas, the most common use is to clamp a graphite electrode with two iron clips for fastening operations, and there is also a “soil wrench” without a torsion structure. However, this type of tightening method not only needs to rely on the experience of master craftsmen but also faces the challenge of uneven quality of graphite electrodes from different manufacturers. A slight difference in the tightening force will make the current flow unstable. It leads to a series of problems such as the electrode is not tightened, the electrode is broken, and so on. Not only does it affect production, but it also consumes electricity, and the work efficiency and graphite electrode utilization rate are relatively low, which increases production costs.

The special graphite electrode wrench can perfectly solve these problems. It is widely used in the smelting industry in other regions. The special wrench for graphite electrodes is not only a tool for tightening graphite electrodes but also a kind of torque tool. Its appearance ended the smelting industry’s production history of relying on experience and technology when installing and replacing graphite electrodes. It provides a reliable guarantee for safe production, energy saving, and high efficiency, and cost reduction in the smelting industry.

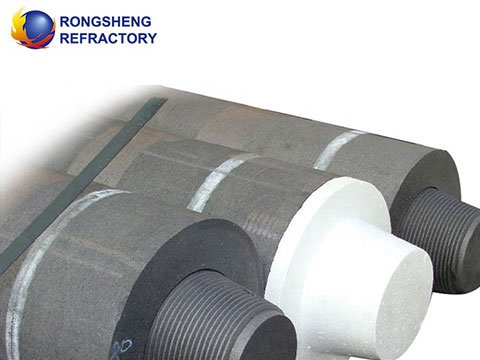

Rongsheng graphite electrode manufacturer specializes in the production and sales of various types of graphite electrodes including graphite electrode with preset nipple products and can customize graphite electrodes and electrode nipples according to the actual needs of customers. Contact us for a free trial.